Wood Working Shaper

Wood Working Shaper Specification

- Core Components

- Spindle, Table, Motor, Guide Fence

- Capacity

- Up to 100 mm thickness

- Power Source

- Electric

- Accuracy

- 0.05 mm

- Measurement Range

- Up to 1500 mm length

- Voltage

- 415 V

- Frequency

- 50 Hz

- Automation Grade

- Semi-Automatic

- Model No

- WW-SH1200

- Temperature Range

- N/A (not applicable)

- Feature

- High accuracy machining, adjustable spindle speeds, robust body

- Equipment Materials

- Cast Iron, Alloy Steel

- Type

- Heavy Duty Wood Working Shaper

- Usage

- Shaping and profiling wood edges in furniture and carpentry work

- Display Type

- Manual (No digital display)

- Dimension (L*W*H)

- 1100 x 800 x 1200 mm

- Weight

- Approx. 320 kg

About Wood Working Shaper

Edutek are offering a wide range of Wood Working Shaper Machines .

- Use: Making shapes and patterns

- Working table 1000x800 mm

- Cutting height 120mm

- Dimension of spindle 35mm

- Spindle rotation speeds 3000/4000/6000/8000/10000 rpm

- Motor power 5.5kw, Net weight 370kg

- Overall dimensions(LxWxH) 1100x1000x1100mm

- Working table 1000x800mm

- Dimension of spring catch 12.7mm

Precision & Performance

Engineered for exacting carpentry needs, the WW-SH1200 delivers remarkable accuracy and consistent performance. The spindle supports a cutter diameter up to 180 mm, adjustable across four speed settings. With a heavy cast iron frame and a 3 HP motor, this shaper ensures stability at every stage of operation.

Safety & Usability

Operator safety is paramount. The built-in emergency stop and spindle lock protect users during setup and operation. Manual controls allow hands-on precision without complex digital interfaces. With noise levels not exceeding 80 dB, it creates a more comfortable working environment.

Versatility in Woodworking

This model suits a wide range of furniture making and carpentry tasks. Capable of handling wood pieces up to 100 mm thick and 1500 mm long, it meets the demands of small-scale artisanal projects to large production batches. Its sturdy table and adjustable fence enable robust, repeatable results every time.

FAQs of Wood Working Shaper:

Q: How do I adjust the spindle speed on the WW-SH1200 Wood Working Shaper?

A: The WW-SH1200 offers four spindle speeds between 5000 and 8000 RPM. You can change the speed manually using the control levers located on the side panel, allowing you to adapt the shaper to various wood types and cutting profiles.Q: What safety features are included to ensure operator protection?

A: This shaper is equipped with an emergency stop button and a spindle lock, which helps secure the cutter during tool changes or maintenance. These features minimize risk and keep both operators and equipment safe during use.Q: When should I use this specific model for my woodworking needs?

A: The WW-SH1200 is ideal for professional workshops focusing on furniture or advanced carpentry. Use this model when your project demands high accuracy, robust machining, and capacity to work with components up to 100 mm in thickness and 1500 mm in length.Q: Where is the WW-SH1200 typically installed or used?

A: This heavy-duty shaper is designed for use in industrial workshops, manufacturing units, and carpentry facilities. Its weight and table size require solid, level flooring within a dedicated workspace for optimal performance.Q: What is the maintenance process for the spindle and motor?

A: Regular maintenance involves cleaning debris, lubricating moving parts, periodically checking the spindle for wear, and ensuring the motor is clear of dust. Always disconnect the power and use the spindle lock before performing maintenance tasks.Q: How does the adjustable spindle speed benefit woodworking operations?

A: Adjustable spindle speed lets you match cutting conditions to different woods and cutter types, enhancing finish quality and extending the life of your cutting tools while reducing material waste and operational risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Building And Civil Engineering Equipment Category

TRI-AXIAL TEST SET

Model No : TAT2024

Automation Grade : Semiautomatic/Automatic

Feature : Highly Efficient

Type : Automatic/Manual TriAxial Test Set

Equipment Materials : Mild Steel Frame, corrosionresistant finish

Power Source : Electric

PERMEABILITY TEST SYSTEM

Model No : PTS01

Automation Grade : SemiAutomatic

Feature : Highly Efficient

Type : PERMEABILITY TEST SYSTEM

Equipment Materials : Mild Steel (Powder Coated), Glass, Stainless Steel Fittings

Power Source : Electric

GUILLOTINE SHEARS

Model No : Custom/Varies by Manufacturer

Automation Grade : SemiAutomatic / Automatic

Feature : Highly Efficient

Type : Mechanical and Hydraulic

Equipment Materials : Highgrade Steel (Frame & Blades)

Power Source : Electric

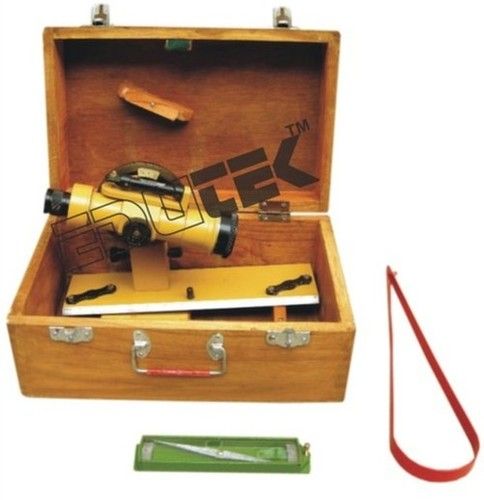

Telescopic Alidade

Model No : TA100

Automation Grade : Manual

Feature : Precision measurement compact design

Type : Surveying Equipment

Equipment Materials : Brass Wood

Power Source : None

Send Inquiry

Send Inquiry