Axial Flow Turbo Machines

Product Details:

X

Product Description

AXIAL-FLOW TURBO MACHINES

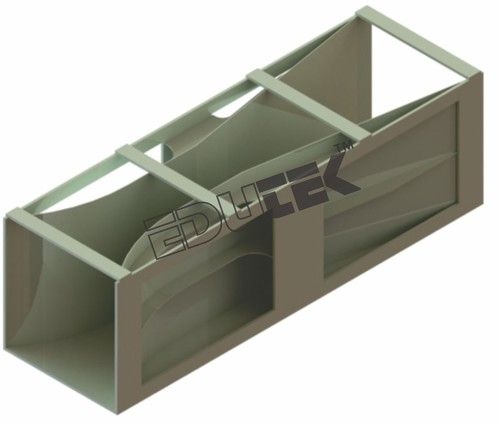

The core piece of the experimental plant is the axial turbomachine with attached asynchronous motor. It can be operated either as a pump or turbine. To this end, different rotors /impellers and stators / guide vane systems are used. Included in the scope of delivery are four rotors / impellers and four stators / guide vane systems supplied with different blade / vane angles. The experimental plant contains a closed water circuit with expansion tank and centrifugal pump. The compressed-air powered expansion tank allows the turbomachine to be converted without loss of water.The asynchronous motor functions during turbine operation as a generator, and during pump operation as a drive. A powerful pump generates flow and pressure during turbine operation. The power that is generated by the turbine is fed into this pump.

The speed is detected contact-free by means of an inductive displacement sensor on the motor shaft. To determine the drive power, the asynchronous motor is mounted on swivel bearings and equipped with a force sensor to measure the drive torque. Manometers measure the pressures at inlet and outlet. Pressure sensors measure the differential pressures at rotor / impeller and stator / guide vane system. The flow rate is measured by an electromagnetic flow meter. The measured values are read from digital displays.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

- The unit shall perform the following experiments and investigations:

- Learning Objectives [Experiments

- Recording characteristic curves

- Determining dimension less characteristics

- Velocity triangles and pressure curves

- Investigation of energy conversion within the turbomachine

- How blade / vane shape affects power and efficiency

- Determining the outlet angular momentum and its effect on the power

- Cavitation effects

Specification:

- Investigation of an axial flow turbomachine

- Closed water circuit with expansion tank and centrifugal pump

- Turbomachine may be operated as a turbine and as a pump

- Two sets of impellers and guide vane systems for pump mode and two sets of rotors and stators for turbine mode with different inlet and outlet angles

- Asynchronous motor with 4-quadrant Operation via frequency converter

- Recovery of the brake energy

- Motor with pendulum bearing, torque measurement via lever arm and force sensor

- Inductive speed sensor on the motor

- Manometers for measuring the inlet and outlet pressures

- Measuring probe and differential pressure sensor for recording the pressure curve in the turbomachine

- Electromagnetic flow meter

- Display of power consumption, torque, speed, pressure, differential pressure and flow rate

- Technical Data

- Centrifugal pump

- Power: 5,5kW

- Max. flow rate: 150m3/h

- Max. head: 10m

- Asynchronous motor

- Power: 1,5kW

- Torque: ...5Nm

- Speed: 0...3000min-1

- Expansion tank: 1501_

- Measuring ranges

- Pressure (manometer): 2x -1...5bar

- Differential pressure: 5x 0...500Mbar

- Flow rate: 0...100m3/h

- Speed: 0...3000min-1

- Torque: 0...9,81Nrn

- Dimensions and Weight

- LxWxI-1: 3350 x 850 x 2465mrn

- Weight: approx..570kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

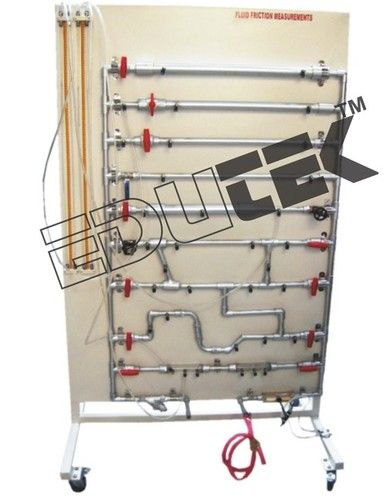

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |