Mass Transfer Lab EquipmentsEmbrace the reliability of our Mass Transfer Lab Equipments, as we are a leading exporter, manufacturer, distributor, and supplier of these products. Our product list includes Wetted Wall Column, Batch Crystallizer, Liquid-Liquid Extraction in Packed Tower, Natural Draft Tray Dryer, and Vapour in Air Diffusion Apparatus. These equipments are specifically designed for Mass Transfer Lab applications. With over 51 years of experience, we offer the best and immaculate quality products in the market. Our Mass Transfer Lab Equipments are known for their supreme features and advantages. Instant savings can be found by purchasing our products, as we offer them at competitive prices. Our products are available in the domestic market all over India and we also export to Africa. Don't miss out on our sale and find the perfect Mass Transfer Lab Equipment for your needs. |

MASS TRANSFER WITH & WITHOUT CHEMICAL REACTION (SOLID -LIQUID) APPARATUS

Specification: MASS TRANSFER WITH & WITHOUT CHEMICAL REACTION (SOLID -LIQUID) APPARATUS Power: 500 Watt (w) Material: Metal Usage For: Laboratory Voltage: 220 Volt (v) Equipment Materials: SS Temperature Range: 50 Celsius (oC) Display Type: Digital

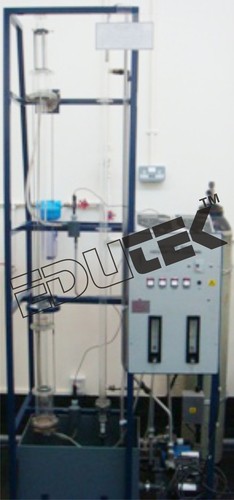

VAPOUR-LIQUID EQUILIBRIUM SET-UP APPARATUS

Specification: VAPOUR-LIQUID EQUILIBRIUM SET-UP APPARATUS Edutek manufactures and supplies optimum quality Vapour Liquid Equilibrium Set-Up, useful in study of the vapor-liquid equilibrium. This robustly constructed product is easy to operate and maintain. Input voltage: 100240V AC Frequency: 50/60Hz Tidal volume range (V t): 0 mL to 1,500 mL Patient airway pressure range: -2kPa 10kPa

HUMIDIFICATION & DEHUMIDIFICATION SETUP APPARATUS

Specification: HUMIDIFICATION & DEHUMIDIFICATION SETUP APPARATUS Description: The setup consists of two glass columns with packings of rushing rings and silica gel. Air flow rates can be set and measured by Rotameter and temperature by RTD type temperature sensors. Flow rate of air and water if measured by rotameter. Experimentation: To calculate Humidity for humidification & dehumidification. To calculate the mass transfer coefficient in the Humidification column. Product Details: Voltage: 220 Volt (v) Material: Metal Power: 500 Watt (w) Equipment Materials: SS Temperature Range: 50 Celsius (degree C)

SWENSON WALKER CRYSTALLIZER APPARATUS

Specification: SWENSON WALKER CRYSTALLIZER APPARATUS The set-up is designed to demonstrate and stimulate the phenomena of crystallization. Swenson Walker crystallizer is a continuous type crystallizer. This operation involves both heat and mass transfer. Crystallization is the formation of solid particles within a homogeneous phase. Its wide use has a two-fold basis; a crystal formed from an impure solution is itself pure. The setup consists of a top open jacketed round bottom trough. A ribbon mixer is provided in crystallizer trough, which rotates at low rpm for agitation of saturated solution. The saturated solution is prepared in a tank fitted with heater and a stirrer. This hot saturated solution is fed at one end of the crystallizer and flows slowly towards the other end while being cooled and is allowed to flow back in hot feed tank making the process continuous. The crystals sediments at the bottom of the trough, and can be washed out at the end of process. Arrangement for Cooling water circulation and flow measurement in jacket is made by using storage type water tank, a pump and a rotameter. Necessary instrumentation is done for temp measurement Experiments To study the performance of a Swanson Walker Crystallizer. To determine the crystal yield and the efficiency of crystallizer. Features Superb Painted structure. Simple to operate & maintain. Compact & standalone set up. Utilities Required Chemicals commercial grade material as per choice.

SOLID-SOLID EXTRACTION APPARATUS

Specification: SOLID-SOLID EXTRACTION APPARATUS Contaminants may be present sorbed in the solid particles of the soil. Solid-liquid extraction allows these contaminants to be removed from the soil. Depending on the contaminant and the type of soil, a suitable solvent needs to be selected for this process. One field of application for example, is the separation of organic contaminants that are present sorbed in fine solid particles. Solid-liquid extraction may take place after these fine particles have been separated by a hydrocyclone in the ex-situ treatment of contaminated soil. The fundamental principle of solid-liquid extraction can be learned with the temperature of the solvent can be adjusted. Thus, it is possible to investigate the effect of this parameter on the separation process. The principle of counter current in solid-liquid extraction: Extraction material inflow, A Path of the extract, B Path of the extraction material Extract outlet, Extraction residue, Extractant inflow,

ION EXCHANGER APPARATUS

Specification: ION EXCHANGER APPARATUS Column (2 Nos.): Material Borosilicate Glass / Stainless Steel Dia 55mm, Length 500mm approx. (For Anion & Cation) Water Tank: Material Stainless Steel, Capacity 25 Ltrs. Bench Area: 1.2 m x 1 m Electricity Supply: 1 Phase, 220 V AC, 0.5 kW Piping: Stainless Steel and PVC Size: 1/4 Inch Feed Circulation: FHP Pump Tullu / Champion make Flow Measurement: Rotameter, Eureka make Conductivity Measurement: Digital Conductivity Meter

SIMPLE BATCH DISTILLATION SETUP APPARATUS

Specification: SIMPLE BATCH DISTILLATION SETUP APPARATUS The equipment consists of a distillation still made of stainless steel. Feed in the still is heated externally by heater. The vapours form at the top of the vessel, are condensed in condenser by circulating cooling water. Temperature of the feed mixture is controlled by means of a digital temp. Controller. The condensate is collected in a receiver made of stainless steel. Product Specification Flow measurement: Rotameter for cold water for condenser Distillation still: Material Stainless Steel, capacity 5 ltrs. (approx.) Insulated with ceramic wool and cladding with A Condenser: Concentric Tube type (Material- Stainless Steel) Distillate tank: Material- Stainless Steel, capacity 2 Ltrs. Heater: Nichrome wire heater.

VACUUM TRAY DRYER APPARATUS

Specification: VACUUM TRAY DRYER APPARATUS VACUUM TRAY DRYER (VTD) is used mainly for drying of high grade, temperature and oxygen sensitive products. Vacuum Tray Dryer is highly suitable for drying hygroscopic substances, which are dried to very low residual moisture, content level. Available Capacity (No. of Trays) “ 6, 24, 48, 96 and 192. MOC- MS/ SS 304/ SS 316/ SS 316L Tray size in air tray dryer is same in all different capacity (800mmX400mmX32mm). Trolley provided for easy loading and unloading of trays as optional.

STEAM DISTILLATION COLUMN APPARATUS

Specification: STEAM DISTILLATION COLUMN APPARATUS The equipment consists of jacketed pressure vessel for distillation. Steam from a steam generator can either be allowed to enter in the outer jacket or in the vessel. The vapours form the top of the vessel are condensed in the shell and tube type condenser by circulating cooling water, supplied by laboratory overhead tank. The condensate is collected in a separating chamber. The set-up is fitted with steam trap, control valves, pressure gauge, temperature sensors and other instrumentations required. Steam distillation is used industrially to purify liquids, which are immiscible with water, and to remove bad odors from oils. When water is added to a high boiling liquid immiscible with it, the total pressure exerted by the mixture above the liquid surface will be the sum of the vapor pressures of the pure components and therefore the boiling point of the mixture will be less than that of water at the given temperature. Because of this, even high boiling liquids are made to boil at low temperature and their decomposition is avoided. The steam consumption for steam distillation process is normally high. Experimentation To study the characteristics of Steam Distillation. Efficiency of simple steam distillation set-up.

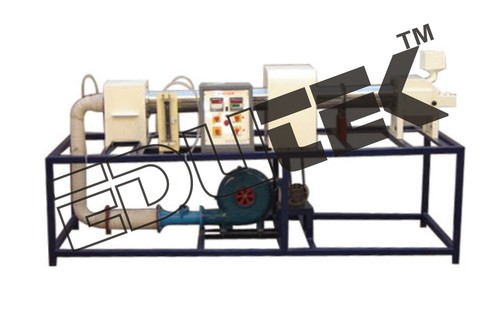

FORCED DRAFT TRAY DRYER APPARATUS

Specification: FORCED DRAFT TRAY DRYER APPARATUS Our organization holds expertise in offering premium quality Forced Draft Tray Dryer to our valuable customers. Manufactured as per the industry set standards, these forced draft tray dryers are widely used for the purpose of analyzing the rate of drying of wet sawdust. The offered analyzing is performed under a wide range of different temperature conditions. Specifications: Electric supply: Provide 230 +/- 10 VAC, 50 Hz, single phase electric supply with proper earthing. 5A, three pin socket with switch for weighing scale, 15A, three pin socket with switch for heater Material: Saw dust 1Kg. Anemometer: Air flow measurement

ABSORPTION IN PACKED BED APPARATUS

Specification: ABSORPTION IN PACKED BED APPARATUS Edutek We are offering superior quality Adsorption in Packed Bed to the esteemed customers, as per their specific demands. These are designed under the strict command of our quality analyzers keeping in mind the industry guidelines. We make sure to timely deliver the ordered products at the customers end, via our wide distribution network. Utilities Required: Water Supply & Drain Electricity Supply: I Phase, 220VAC, 1.5kW Instruments, Laboratory Glassware and Chemicals required for analysis as per the system adopted Specifications: Product: Adsorption Setup Reactor Column: Material Borosil Glass, different diameter with different height of packing (3 Nos.) Feed Tank: Material Stainless Steel, Capacity 20 Ltrs., feed lines, drain valve etc. (1Nos.) Receiving Tank: Material Stainless Steel, Capacity 20 Ltrs (1Nos.) Feed Circulation: By pump, Magnetic drive made of Polypropylene (1Nos.) Flow Measurement: Rota-meter 1 Nos. (For feed) Feed Piping: PVC, SS size Stop Watch: Electronic Control Panel: On off switch, Mains Indicator etc.

FLUIDIZED BED DRYER APPARATUS

Specification: FLUIDIZED BED DRYER APPARATUS Description: This is a dryer in which moisture removal takes place by fluidization of solids particles by hot air. The set-up fitted with a specially designed, vertical Glass Column. The lower portion of the column is filled with fluidizing material. The material is supported on the screen mesh held between two flanges. Air from a compressor is heated in the heater box and passed through the column. Flow control and by-pass valve are fitted to regulate the airflow. At the top outlet of column a cyclone is provided to collect any solid particles taken out by the air stream. Experimentation: To study the fluidized bed drying. To plot the drying curve under fluidized bed condition. Utilities Required: Electricity Supply: 1 Phase, 220 V AC, 3 kW. Granular and free flowing solid of size 1 to 2 mm. Technical Details: Control panel comprises of : Digital Temp. Controller: 0 199.9C (For Hot Air) Standard make on/off switch, Mains Indicator etc. Column: Material Borosilicate Glass Dia. 80 mm. Total Length 500mm. Cyclone Separator: Material Stainless Steel, Compatible Capacity with collector. Air Circulation: By forced draft fan, Arrangement is done vary the air flow rate. Heating Chamber: Compatible capacity Heater: Nichrome wire heater Temperature Sensors: RTD PT-100 type.

BATCH CRYSTALLIZER APPARATUS

Specification: BATCH CRYSTALLIZER APPARATUS Description: Crystallization is the formation of solid particles within a homogeneous phase of saturated liquid. Its wide use has a two-fold basis, a crystal formed from an impure solution is itself pure and crystallization affords a practical method of separating. This operation involves both heat and mass transfer. Cooling type agitated batch crystallizer set up consists of an open jacketed stirred vessel provided with water heating & cooling arrangement. The feed is prepared in the crystallizer itself with hot water and stirrer. The hot saturated solution in the crystallizer is then cooled by circulation of cooling water and crystals are formed. Experimentation: To study the performance of a Batch Crystallizer. To determine the crystal yield and the efficiency of crystallizer. Utilities Required: Water Supply. Drain. Electricity Supply: 1 Phase, 220 V AC, 1.5 kW. Required Chemicals. Technical Details: Crystallizer (Jacketed Type): Material Stainless Steel, Cap. 2 Ltrs. with conical bottom Stirrer: FHP, Variable Speed. Heater: Nichrome wire heater Cooling Water Tank: Material Stainless Steel, Capacity 30 litre fitted with Pump. Flow measurement: Rotameter for cooling water. Pump: FHP. Receiving Tank: Material Stainless Steel , Capacity 2 litre with SS sieve Temp. Sensors: RTD PT-100 type Control panel comprises of: Digital Temp. Indicator: 0-199.90C with multi-channel switch and Standard make on/off switch, Mains Indicator etc.

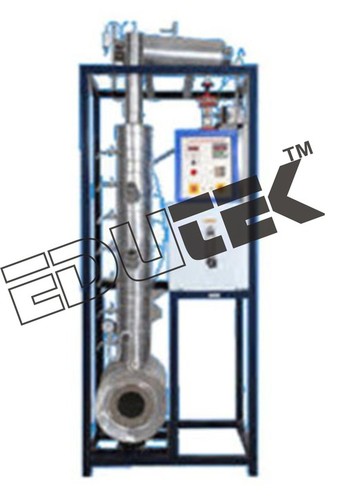

SIEVE PLATE DISTILLATION COLUMN APPARATUS

Specification: SIEVE PLATE DISTILLATION COLUMN APPARATUS Having extensive knowledge and rich understanding of the market, we are able to manufacture and export a premium range of Sieve Plate Distillation Column. Made and designed using quality stainless steel with seven sieve trays, these columns are used for demonstrating the principles of distillation in a sieve plate. Our Sieve Plate Distillation Column is best known for numerous quality features such as simple operation, less maintenance and compact design. We adhere to the parameters of the national and international quality standards to provide the clients with utmost satisfaction in terms of quality. Features: Ruggedness Lightweight Longer service life Further Details: The setup is designed to demonstrate principles of distillation in a Sieve Plate Column. The column is made of Stainless Steel material with seven sieve trays. An electrically heated re-boiler is installed at the bottom of the column. The bottom product is collected in the tank. The vapors form the top of column are condensed in the shell and tube type condenser by circulating cooling water supplied by laboratory overhead tank. The condensate is divided into reflux & distillate and R/D Ratio can be varied. Reflux is fed back to the column and distillate is received in a receiving tank. The complete column is insulated for minimizing the heat loss. Instrumentation is done for pressure & temp. Measurement wherever is necessary. Experiments: To study the Sieve Plate Distillation Column Features: Stainless Steel tanks and wetted parts Superb Painted structure Simple to operate & maintain Compact & standalone set up Utilities Required: Water Supply 2 LPM at 5 m head Drain Electricity Supply: 1Phase, 220 V AC, 6.5 kW Required Chemicals Refractrometer for analysis Technical Details: Distillation Column Material Stainless Steel Dia 100 mm Packing Material Sieve plates seven nos. Rota meter For cooling water flow rate measurement. Re-boiler Made of Stainless Steel, provided with Pressure gauge (Bourdon type, 0-2kg/cm2) & Level Gauge. Safety valve & insulated with ceramic wool Condenser Shell & Tube Type made of Stainless Steel. Collection Tank Distillate & bottom product capacity 5 Ltrs. each Heaters Nichrome wire heater Piping PVC/SS, Temp. Sensors RTD PT-100 type, Control panel Digital Temp. Controller: 0-199.9degC, For Steam Re boiler Digital Temp. Indicator: 0-199.9degC. ,with multi-channel switch On/off switch, Mains Indicator etc. Optional Utility Extra Refractrometer

NATURAL DRAFT TRAY DRYER APPARATUS

Specification: NATURAL DRAFT TRAY DRYER APPARATUS Owing to the vast experience and knowledge of this field, we have been able to offer premium quality Natural Draft Tray Dryer to prestigious customers. These dryers are commonly used for analyzing the moisture elimination by various condition of high temperature under natural draft action. This draft action is generated by the hot stream of air. Specifications: Electric supply Provide: 230 +/- 10 VAC, 50 Hz, single phase electric supply with proper earthing. 5A, three pin socket with switch for weighing scale, 15A, three pin socket with switch for heater. Material Saw dust 1Kg. Support table Size: 500W x 500D x 750H in mm.

VAPOUR IN AIR DIFFUSION APPARATUS

Specification: VAPOUR IN AIR DIFFUSION APPARATUS The setup comprises all needed accessories for determining the diffusion coefficient of vapors (liquid) in air phase. The diffusion vessel is of high-quality Borosilicate Glass, along with a T type diffusion tube engraved in mm scale for level readings. The vessel is mounted over a Magnetic Stirrer cum hot plate, given with controls for vary the temperature and RPM for calculating the diffusion rate at different temperature. The Air Flow stream is created making use of mini-air pump. Diffusivity of the vapors is determined by WINKELMANN method, in which liquid evaporates in a graduated vertical glass tube over the top of which a stream of air is passed. Experiments Determining diffusion coefficient for liquid / vapor in air system Features Painted structure Simple to operate and maintain Compact set up

SOLID IN AIR DIFFUSION APPARATUS

Specification: SOLID IN AIR DIFFUSION APPARATUS The set up comprises glass column, air rotameter, piping and packing material. Metered quantity of airflow is passed through the vertically upwards packed bed. The flow rate can vary for simulating several conditions making use of rotameter. Naphthalene balls are used to form the packed bed for the calculation of mass transfer co-efficient of vaporization in air. Experiments Calculation of the mass transfer co-efficient of vaporization of naphthalene in air, making use of a packed bed of spherical particles of naphthalene. Features: Painted structure Simple to operate and maintain Standalone set up

ROTARY DRYER APPARATUS

Specification: ROTARY DRYER APPARATUS The setup is designed to demonstrate and stimulate the moisture removal by heat under forced draft action created by hot air stream and shower of moist solid due to rotary action of dryer drum. The set-up consists of a long cylindrical shell slightly inclined towards the outlet rotating at low RPM. Counter current hot air from blower passes through heating chamber to produce hot air works as the drying agent entered from one side of the rotating shell and leave from other side removes the moisture from the moist solids. High moisture content feed enters from one end of the shell and low moisture content product discharges from the other end of shell. As the shell rotates internal flights lift the solids and shower them down through the interior of the shell. This action increases the contact of wet solid against hot-air making the dryer very effective. An arrangement is made to vary and measure the airflow rate. A digital temperature controller is used to control and measure the temperature of air stream. Experiments To study the operation of a Rotary Dryer To study the drying characteristics of a solid material under batch drying condition in a rotary dryer Features Superb Painted structure Simple to operate & maintain Compact & standalone set up

ABSORPTION IN SIEVE PLATE COLUMN APPARATUS

Specification: ABSORPTION IN SIEVE PLATE COLUMN APPARATUS The setup is designed to demonstrate principles of distillation in a Sieve Plate Column. The column is made of Stainless Steel material with seven sieve trays. An electrically heated re-boiler is installed at the bottom of the column. The bottom product is collected in the tank. The vapors form the top of column are condensed in the shell and tube type condenser by circulating cooling water supplied by laboratory overhead tank. The condensate is divided into reflux and distillate by automatic reflux divider and R/D Ratio can be varied. Reflux is fed back to the column and distillate is received in a receiving tank. The complete column is insulated for minimizing the heat loss. Instrumentation is done for pressure & temp. Measurement wherever is necessary Experiments To study the Sieve Plate Distillation Column Features Stainless Steel tanks and wetted parts Superb Painted structure Simple to operate & maintain Compact & standalone set up Utilities Required Drain Electricity Supply: 1Phase, 220 V AC, 6.5 kW Required Chemicals Refractrometer for analysis

ABSORPTION IN WETTED WALL COLUMN APPARATUS

Specification: ABSORPTION IN WETTED WALL COLUMN APPARATUS Heat and mass transfer during the process in a wetted wall column can be demonstrated and studied by this set-up. The major parts of this set-up comprises: Glass column Feed tank Air regulator with pressure gauge Rotameter Receiving tray and piping Disturbance in metered quantity of fluid and walls of column occurs from the top, as metered hot air flow is passed through the wetted wall column vertically upwards and evaporation in the liquid film around the wall occurs. Different conditions can be stimulated by varied flow rates of water and air. Experiments Determination of the gas film coefficient in a wetted wall column making use of air water system. Finding the mass transfer coefficient Features Well Painted structure Simple operation and maintenance Compact and standalone set-up Utilities needed Water supply and drain 1Phase, 220 V AC, 0.5 kW is electricity supply

SPRAY TOWER APPARATUS

Specification: SPRAY TOWER APPARATUS The setup is designed to demonstrate principles of spray extraction and mass transfer operation in a column. The set up consists of a glass column, feed tanks, air regulator with pressure gauge, receiving trays and piping. Rotameter are provided for flow measurement Experiments Determination of overall height of a transfer unit and overall volumetric mass transfer coefficient Features Stainless Steel tanks and wetted parts Special arrangement for changing height of interface zone Continuous operation Superb Painted structure Simple to operate & maintain Compact & standalone set up Utilities Required Electric supply Provide 230 +/- 10 VAC, 50 Hz, single phase electric supply with proper earthing. 5A, three pin socket with switch for Compressor Chemicals for trial as per your choice Compressed Air supply: Clean, oil and moisture free air, pressure 2 Bar. Water Supply & Drain as required

BUBBLE CAP DISTILLATION COLUMN APPARATUS

Specification: BUBBLE CAP DISTILLATION COLUMN APPARATUS Edutek The column is made of Stainless Steel with seven plates for mounting the bubble caps. Each plate is provided with one bubble cap. An electrically heated re-boiler is installed at the bottom of the column. The vapors form the top of column are condensed in the shell and tube type condenser by circulating cooling water supplied by laboratory overhead tank. The condensate is divided into reflux and distillate by automatic reflux divider and R/D Ratio can be varied. Reflux is fed back to the column and distillate is received in a receiving tank. The complete column is insulated for minimizing the heat loss. Instrumentation is done for pressure & temp measurement wherever is necessary

YORK SCHEIBEL EXTRACTION UNIT APPARATUS

Specification: YORK SCHEIBEL EXTRACTION UNIT APPARATUS The setup is designed to demonstrate principles of extraction and mass transfer operation in a YORK SCHEIBELS column. The set up consists of a glass column, feed tanks, and air regulator with pressure gauge, receiving tanks and piping. Rotameter are provided for flow measurement. The glass column is divided into multiple stages; each stage consists of a woven wire mesh (calming) section and a mechanical agitation section. The agitator speed can be varied by drive. The presence of alternatively agitating and calming sections yield higher extraction efficiency than conventional packed column Experiments Determination of overall height of a transfer unit and overall volumetric mass transfer coefficient Features Stainless Steel tanks and wetted parts Special arrangement for changing height of interface zone Continuous operation Superb Painted structure Simple to operate & maintain Compact & standalone set up Utilities Required Electric supply Provide 230 - 10 VAC, 50 Hz, single phase electric supply with proper earthing. 5A, three pin socket with switch for Compressor Compressed Air supply: Clean, oil and moisture free air, pressure 2 Bar. Chemicals for trial as per your choice Water Supply & Drain as required

LIQUID- LIQUID EXTRACTION IN A PACKED TOWER APPARATUS

Specification: LIQUID- LIQUID EXTRACTION IN A PACKED TOWER APPARATUS Edutek has designed this setup for demonstrating principles of liquid-liquid extraction and mass transfer operation in a packed column. This set up comprises the following: Glass column Packing Feed tanks Air regulator with pressure gauge Receiving tanks Piping Rotameter for flow measurement Experiments Determination of overall height of a transfer unit and overall volumetric mass transfer coefficient Features: SS tanks and wetted parts Simple operation & maintenance Compact & standalone set up Special arrangement for changing height of interface zone Continuous operation Painted structure Utilities Required Electric supply: 230 +/- 10 VAC, 50 Hz, single phase electric supply with proper earthing 5A, three pin socket with switch for Compressor Water supply & drain Chemicals for trial Compressed air supply: Clean, oil and moisture free air, pressure 2 Bar

Liquid-Liquid Extraction in Packed Tower

- Delivery Time:2 Week

|

|

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |