Wetted Wall Column

Product Details:

X

Product Description

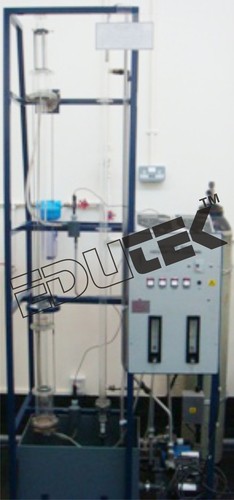

Wetted Wall Column:DESCRIPTION :

The set up consists of a glass column. Water is fed at the top of the column along the walls to make the column a wetted wall column. Hot air from heating chamber with known humidity is allowed to pass through the column vertically upward and evaporation in the liquid film around the wall takes place. The flow rates of water and air can be independently varied to simulate different conditions. Instrumentation is provided to measure the dry and wet bulb temperatures at air inlet and outlet.

EXPERIMENTATION:

- To determine the gas film coefficient in a wetted wall column using air-water system.

- To find the mass transfer coefficient

- Compressed Air Supply at 2 Bar, 4 CFM.

- Water supply.

- Drain.

- Electricity Supply : 1 Phase, 220 V AC, 0.5 kW.

- Column : Borosilicate Glass Dia 45 mm, Length 1000 mm (approx.)

- Water Circulation : FHP Pump.

- Water Tank : Material Stainless Steel, Capacity 20 Ltrs.

- Heating Chamber : Compatible capacity.

- Heater : Nichrome wire heater

- Rotameter : For water flow rate measurement.

- Dry & wet Bulb Temp. : With Digital Temperature Indicator.

- Temperature Sensors : RTD PT-100 Type.

- Control panel comprises of :

- Digital Temp. Indicator : 0-199.90C, RTD PT-100 type with multi-channel switch. Standard make on/off switch, Mains Indicator etc.

- Instruction Manual : An ENGLISH instruction manual will be provided along with the Apparatus

- The whole set-up is well designed and arranged in a good quality painted structure.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Mass Transfer Lab Equipments ' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |