Engineering Testing EquipmentPresenting our innovative Engineering Testing Equipment, which includes top-of-the-line products such as the CAR ENGINE ANALYZER, DIGITAL HIGH DISCHARGE BATTERY TESTERS, CROSSHOLE SEISMIC EQUIPMENT, Analogue Hydrostatic Pressure Testing Equipment, and Inclined Plane Tester. Our company, with over 51 years of experience, is a leading exporter, manufacturer, distributor, and supplier of these must-have tools for any engineering testing application. Our Engineering Testing Equipment has a supply ability in the domestic market throughout All India and is also exported to Africa. Our Engineering Testing Equipment offers five superb advantages and features, including perfect accuracy, gorgeous design, high durability, easy operation, and reliable performance. Whether you are testing engines, batteries, or structures, our products are specially designed to meet your needs and exceed your expectations. With our Engineering Testing Equipment, you can be sure that your testing results are accurate, reliable, and consistent. |

BERNOULLIS THEOREM APPARATUS.

Specification: BERNOULLIS THEOREM APPARATUS Our organization is counted among the listed manufacturers, wholesalers and exporters of premium quality Bernoullis apparatus. Offered apparatus is precisely manufactured under strict supervision in compliance with industry laid parameters. These units consist of a rectangular transparent flow section through which water is to be flown. The velocity of water changes across the sectional area of channel changes. Experiments: To verify Bernoullis Theorem experimentally Utilities Required: Electric supply 0.5 kW, 220V AC, Single Phase Water supply Tap water connection BSP Distilled water 60 liters (optional) Floor Area with Drain facility Technical Specifications: Electric supply: 0.5 kW, 220V AC, Single Phase Inlet Tank Capacity: 20 Ltrs. MOC SS Supply Tank Capacity: 85 Ltrs. MOC SS Measuring Tank Capacity: 40 Ltrs. MOC SS fitted with Piezometer Tube & scale Piezometer Tubes: Material P.U. Tubes (9 Nos.)

RECTANGULAR OVERSHOT WEIR/ BOARD CRESTED WEIR

Specification: RECTANGULAR OVERSHOT WEIR/ BOARD CRESTED WEIR We have marked a remarkable position in the market by offering the best quality array of Broad Crested Weir. Features: Elevated durability Dimensional accuracy Easy usage

FLOW OVEN NOTCHES

Specification: FLOW OVEN NOTCHES Offered by us are high-quality Flow over Notch to the esteemed customers, as per their specific requirements. These products are used for the purpose of testing and demonstrating the industrial machinery, thus, are highly demanded in the market. Our range of Flow over Notches is used to read and calculate the flow of water in metric units. Product Details: High-quality materials used Highly stable Extremely durable Reliable results Hassle-free flow of water all over the setup Robust shape

LOSSES DUE TO FRICTION IN PIPE LINES

Specification: LOSSES DUE TO FRICTION IN PIPE LINES We offer highly demanded Losses due to friction in pipe line at the most competitive market price. Manufactured in accordance with the industry laid parameters, offered apparatus is highly demanded around the globe. The setup is designed to study the losses due to friction in pipes of different diameters and materials. This consists of a set of 3 different pipe test sections, supply tank, measuring tank and pump for closed loop water circulation. Experiments: To determine the losses due to fiction in pipes Utilities Required: Electric supply 0.5 kW, 220V AC, Single Phase Water supply Tap water connection BSP Distilled water 60 liters (optional) Floor Area with Drain facility Technical Specifications: Pipes (2 Nos.): Material GI of 1/2 & 1 diameter. Pipe Test Section Length: 1 m. Instruction Manual: An ENGLISH instruction manual will be provided along with the Apparatus

HUMP .

Specification: HUMP Objectives To study the variation in flow due to introduction of different types of humps or weirs in the flume. Flow Characteristics over Hump Hump It is a structure or obstruction that is constructed across a river or stream to raise the level of water on upstream side so that it can be diverted to canals to meet the irrigation requirements.

SIPHON SPILLWAY

Specification: SIPHON SPILLWAY Made of transparent plexiglass, 3mm thickness, Dimensions: 100x216x287h, Support made of black anodized aluminum, designed for, Installation on sliding trolleys on the channel, Overall dimensions: 299x360x350h mm.

CRUMP WEIR

Specification: CRUMP WEIR A crump weir model to demonstrate alternative flow measurement techniques used in rivers and waterways.

PITOT TUBE & MANOMETER BOARD

Specification: PITOT TUBE & MANOMETER BOARD 5 Selectable Units Of Pressure Measurement 5 Selectable Units Of Pressure Measurement Large Backlit LCD Display Easy To Calculate The Area Of A Rectangular Or Circular Duct

VENTURI FLUME

Specification: VENTURI FLUME A venturi flume is a critical-flow open flume with a constricted flow which causes a drop in the hydraulic grade line, creating a critical depth. It is used in flow measurement of very large flow rates, usually given in millions of cubic units Product Specification Usage/Application: Educational purposes Material: Stainless Steel Phase: Single Phase Accuracy: 100% Country of Origin: Made in India

BASIC HYDROLOGY SYSTEM

Specification: BASIC HYDROLOGY SYSTEM Technical Data Tank: Stainless steel 100 cm wide x 200 cm long x 19 cm high. Inclination: 0-3%. End compartments: 2 ea. Wells: 2 ea. Spray nozzles: 8 nozzles with separate shutoff valves. Flow measurement Rain water: Variable area flow meter. Run off: Calibrated weir. Manometer: 1 ea. Upper walls: Clear acrylic. Accessories: - Rectangular ring, circular ring, confined equifer, cylindrical pier. Power supply: 220 V, 1 Ph, 50 Hz. Other power supply is available on request. Typical Tests Investigation of rainfall/runoff relationships for dry, saturated and impermeable catchments of various slopes for surface runoff. Effect of interflow on outflow hydrograph. Simulation of multiple and moving storms. Cone of depression for single well and interaction of cones of depression for two adjacent wells. De-watering of excavation sites by use of wells. Flow from a well in a confined aquifer. Demonstration of watersheds for a simulated island with rainfall and well flows. Sediment transport and meanders in simulated rivers. A metal frame supports the tank and houses a storage tank. Water is drawn from the storage tank by a pump and separately supplied to the overhead nozzles and/or the two end compartments via a flow meter and pipings with valve control. Run-off from the catchment is measured by a calibrated rectangular weir or returns directly to the storage tank.

SLUICE GATE

Specification: SLUICE GATE Sluice gate with lateral sealing lips Height adjustment using hand wheel Scale to read the height of the gate opening Technical data Gate Weir plate made of PVC Head adjustment: 0150mm Dimensions and weight LxWxH: 370x263x710mm Weight: approx. 5kg

PARSHALL FLUME

Specification: PARSHALL FLUME The Parshall Flume is an economical and accurate way of measuring water flow in open channels and non-full pipes. Originally the flume was developed to measure surface waters, water rights apportionment, and irrigation flows. However, its use has expanded to include measuring sewage flow (both in pipe and treatment plants), industrial discharges, dam seepage, and other applications.

RECTANGULAR NOTCH WEIR

Specification: RECTANGULAR NOTCH WEIR Rectangular Weir: A rectangular notch is a thin square edged weir plate installed in a weir channel

IMPACT OF JET ON VANES

Specification: IMPACT OF JET ON VANES We are counted among the most prominent manufacturers, traders and exporters of high-quality Impact of jet of vanes. Designed in compliance with industry leading parameters, It is used to study the forced developed of a jet of water on different surfaces and to compare it with momentum theory. Offered set up consists of visible test enclosure, supply tank, measuring tank and pump for closed loop water circulation. Description The setup consists of a two-sided clear fabrication section. Water is fed through a nozzle and discharged vertically to strike a target carried on a stem which extends through the cover. A weight carrier is mounted on the upper end of the stem. The dead weight of the moving parts is counter balanced by a compression spring. The vertical force exerted on the target plate is measured by adding the weights supplied to the weight pan until the mark on the weight pan corresponds with the level gauge. A total of two targets are provided, a flat plate and a hemispherical cup. Experimentation: To measure the force developed by a jet of water impinging upon a stationary object and comparison with the forces predicted by the momentum theory Utilities required: Hydraulic Bench

FLOW THROUGH ORIFICE & MOUTH PIECE

FLOW THROUGH ORIFICE & MOUTH PIECE Product Specification Material: Mild Steel Finishing Type: Powder Coated ISO Certified: AN ISO 90012015 Product Description: Our company offers optimum quality Orifice and Mouthpiece Apparatus at the most reasonable market price. This apparatus is manufactured under the supervision of expert professionals, using best quality raw materials. The apparatus manufactured by us is used for the purpose of measuring fluid flowing through an open channel. Offered apparatus is exclusively demanded in various hydraulic industries for accurate performance and hassle-free installation. Experiments: To determine the co-efficient of discharge of different Orifice and mouthpiece Utilities Required: Electric supply 0.5 kW, 220V AC, Single Phase Water supply Tap water connection BSP Distilled water 60 liters (optional) Floor Area with Drain facility Technical Specifications: Sudden Enlargement: From 13 mm to 23 mm Sudden Contraction: From 20 mm to 16 mm Electric supply: 0.5 kW, 220V AC, Single Phase

TILTING BED FLOW CHANNEL (LENGTH; 2.5M) WITHOUT ACCESSORIES

Specification: TILTING BED FLOW CHANNEL (LENGTH; 2.5M) WITHOUT ACCESSORIES This apparatus consists of a Flow channel. Channel is fabricated from transparent Toughened Glass and Stainless Steel together. The equipment is designed to study the various phenomenon of flow with the help of various types of blocks, gates, weirs, and other many types of accessories (Optional). The channel section is transparent by which user can observe the various flow patterns of fluid in the channel and photographs can be taken. These glass panels are sealed with the stainless steel bed. This channel is floor mounted. Instrument rail is provided along the entire working length of the flume. A scale is provided along with the rail. A pointer gauge is provided to measure the depth of flow that can move on the rail. At the inlet of the flume an inlet tank with stilling and smoothing device is provided for obtaining the excellent velocity profile in the test section. At the discharge side a gate is provided which have an adjustable height. This gate maintains the operating water levels for the flume. This flume is tilted using a jacking system which has one jack. An arrangement has been done to calculate the slop of channel. The flow channel is self-contained re-circulating unit provided with sump tank, centrifugal pump, and control valve. Water is circulated through the channel by centrifugal pump. The pump draws water from sump tank to inlet tank of flume and return back to sump after passing through the channel. Product Details: Automatic Grade: Manual Voltage: 220 V Backrest Adjustment: 0-75 Deg Capacity: 240 Kg Footrest Adjustment: 0-40 Deg Height Adjustment: 575 - 815 mm

V-NOTCH WEIR

Specification: V-NOTCH WEIR Product Features Vibrating Wire precision water level sensor Simple in, low cost and robust instrument Accurate and sensitive water level monitoring High resolution monitoring Low maintenance system Range: 300mm Resolution*: 0.025% full scale (minimum) Material: Stainless Steel

STANDING WAVE FLUME

Specification: STANDING WAVE FLUME FRP Standing Wave Flumes used for discharge measurement in channels and laboratories are experimentally investigated. Height and width of SWF are the two parameters characterizing the head-discharge relationship. Laboratory experiments are conducted by measuring the discharge and the head over the weir for variable weir heights and widths. Applicability of various formulations for the discharge coefficient are investigated. Specifications: Material: FRP Size: Customized

SPILLWAY .

Specification: SPILLWAY Made of transparent plexiglass 8 mm thickness, Overall dimensions: 200x200x310h mm, Include: Hydraulic jump made of transparent plexiglass and black PVC, Overall dimensions: 150x299x70h mm, Breakwaters: made of black PVC, Overall dimensions: 96x10x170h mm, Apron with Energy Dissipaters made of black PVC, Overall dimensions: 300x299x45h - Wooden Dam, Made of black PVC overall dimensions: 299x400x150h mm.

LOSSES DUE TO PIPE FITTING, SUDDEN ENLARGEMENT & CONTRACTION

Specification: LOSSES DUE TO PIPE FITTING, SUDDEN ENLARGEMENT & CONTRACTION The set up consists of a 1/2 bend and elbow, a sudden expansion & sudden contraction fitting from 15mm to 25mm, ball valve and gate valve. Pressure tapings are provided at inlet and outlet of these fittings under test. A differential manometer fitted in the line gives pressure loss of individual fittings. Present setup is self-contained water re-circulating unit, provided with a sump tank and a centrifugal pump etc. Flow control valve and by-pass valve are fitted in water line to conduct the experiment on different flow rates. Flow rate of water is measured with the help of measuring tank and stop watch. Control Panel Comprises Of: Standard Make On/off Switch, Mains Indicator, Etc. Sump Tank Capacity: 50 Ltrs Flow Measurement: Using Measuring Tank with Pedometer, Capacity: 25 Ltrs Manometer Fluid: Mercury (Hg) - 250 Gm Sudden Enlargement: From 15 mm to 25 mm Sudden Contraction: From 25 mm to 15 mm Bend: 1/2 Elbow: 1/2 Ball Valve: 1/2 Gate Valve: 1/2 Inches Water Circulation: FHP Pump, Crompton Makes Pressure Drop Measurement: Differential Manometer Stop Watch: Electronic

CURRENT METER

Specification: CURRENT METER Fluid: for water Installation: vertical Material: stainless steel Protection level: corrosion-resistant Other characteristics: precision

CORIOLLIS COMPONENT OF ACCELERATION APPARATUS.

CORIOLLI™S COMPONENT OF ACCELERATION APPARATUS We are offering a wide range of Coriolis Component Acceleration. This entire set up is designed to study various coriolis components of a slider crank mechanism. In this process the continuous stream of water which is flowing through a steady rotating pair of tubes replaces mechanical slider system. The tubes of the system can be easily rotated in various speeds with the usage of a swinging field motor which also serves a dynamometer. There is a Perspex window located on the top of the tank. This window assures complete clear view of the process. It also prevents the splashing of water over the side of the tank. The in-built dynamometer continuously measures the torque which is applied to the various rotating tubes. This entire equipment is self-contained. The re-circulating of the water is assisted with a own speed control unit and water circulating pump which is separate. Experimentation To determine Coriolis Component of Acceleration at various speeds of rotation and water flow rates Utilities Required Electricity 0.5 kW, 220 V, Single Phase Drain Water Supply Technical Details: Swinging field type, variable speed Pump, FHP The whole set-up is well designed and arranged in a good quality painted structure Fabricated out of stainless steel Rotating arms 9mm/6mm orifice diameter, length 300 mm Rotameter, Electric motor, Main tank Control Panel comprises of: Speed control unit Standard make On-Off switch, mains indicator RPM indicator with proximity sensor RPM measurement

SERIES & PARALLEL SYSTEM CENTRIFUGAL PUMP DEMONSTRATION

Specification: SERIES & PARALLEL SYSTEM CENTRIFUGAL PUMP DEMONSTRATION Two motor-driven centrifugal pumps, mounted on a stainless steel plinth with a water reservoir and pipework for continuous circulation. The pumps can be configured for single pump operation, two pumps in parallel or two pumps in series by using manually operated ball valves. Similarly, manual valves are used to control the flow and facilitate the study of suction effects, including demonstration of air release. In parallel operation the two pumps draw from a shared inlet pipe of a wider diameter than the pump inlet, reflecting a typical industrial configuration of parallel pumping. Each pump has impellers that can be easily accessed and replaced without tools. This is delivered with three impellers in total one with forward curved blades and two with backward curved blades allowing the students to investigate the effects of impeller characteristics. Electronic sensors measure the pump outlet pressure of each pump the shared pump inlet pressure the flow rate and the water temperature.

FLUID FRICTION APPARATUS.

Specification: FLUID FRICTION APPARATUS Fluid Friction Apparatus Shows flow and losses in different pipes, fittings and valves. Shows popular flow measurement instruments. A space-saving vertical panel that works with Gravimetric or Volumetric Hydraulic Benches for easy installation Includes different valves, pipes and fittings to show losses Includes experiments on roughened pipes Shows laminar and turbulent flow Uses Bernoulli™s equation Shows how to use Venturi and orifice meters to measure flow Includes a traversing Pitot tube to measure velocity profile Fluid Friction Apparatus allows students to study flow, flow measurement techniques and losses in a wide variety of pipes and fittings. The equipment has three water circuits with instruments, pipes and pipe system components. These allow students to examine and compare the different component characteristics. A hydraulic bench (Gravimetric) or Volumetric, available separately) supplies the circuit with a controlled flow of water. A space-saving vertical panel holds all the parts for easy use. To measure pressure loss across components, students use a piezometer set and differential pressure gauge (included). To perform experiments students record the temperature of water in the hydraulic bench and set the hydraulic bench to pump water through a circuit. They measure pressure losses across instruments or components. The hydraulic bench gives an external flow rate for reference and comparison. The flow measurement instruments show students the common methods of measuring water flow. They also give applications of the steady flow energy equation (Bernoulli™s equation). Students use a Venturi meter and an orifice plate meter and compare the losses of each. They also find the losses in a rapid enlargement. The equipment also includes a Pitot-static tube. By traversing the Pitot across the pipe diameter, students can find the velocity profile and flow coefficients. They also find the relationship between the flow rate and pressure differential. An artificially roughened pipe allows students to study friction factor at different Reynolds numbers, covering the interesting transitional flow from laminar to turbulent. They can compare results to those predicted by Nickuradse™s results and a Moody chart. Standard Features: Supplied with a comprehensive user guide. Two-year warranty. Manufactured in accordance with the latest Indian Union directives.

CAVITATIONS APPARATUS.

Specification: CAVITATIONS APPARATUS The apparatus has been designed to demonstrate the phenomenon of cavitation. The present set-up consists of a test section made of Acrylic having conversion and diversion section. Pressure tapings at appropriate position are provided. This test section is having one control valve at upstream side to regulate the water flowrate. Two pressure gauges are connected to these taping which give the pressure readout at the time of flow passing through this test section. Present set-up is self-contained water re-circulating unit, provided with a sump tank, centrifugal pump etc. Water is pumped by means of centrifugal pump and passing through the test section, it returns back to the sump which make the system re-circulating type. Flow of water is diverted either to measuring tank or sump tank with the means of a flow diverter, when needed. Flow control valve and by-pass valve are fitted in water line to conduct the experiment on different flow rates. Flow rate of water is measured with the help of measuring tank with piezometer and stopwatch. The supplied set-up is complete in all respect. Only water supply and electricity supply is to be provided by the end user for running the set-up. Product Specification Test Section: Material Acrylic Pressure Gauge: 0-4 kg/cm2 Vacuum Gauge: 0-760 mmHg Water Circulation: By Pump, Crompton/Standard make. Flow Measurement: Using Measuring Tank, Capacity 40 liters Sump Tank Capacity: 60 Ltrs. Stop Watch: Electronic

HYDRAULIC BENCH WITH 11 ACCESSORIES

Specification: HYDRAULIC BENCH WITH 11 ACCESSORIES We are manufacture Export Quality Hydraulic Bench for Fluid Mechanics Laboratory. Hydraulic bench is a very useful apparatus in hydraulics and fluid mechanics. The Hydraulic Bench is designed as a portable and self-contained service module for the range of accessories to carry out experimentation on principles of Fluid Mechanics. Wide range of accessories are available for use with Hydraulic Bench that cover a number of experiments to study principles of fluid mechanics. The whole set-up is well designed and arranged in a good quality painted structure Experiment of Hydraulic Bench Bernoullis Theorem Apparatus Flow measurement by Venturimeter Flow measurement by Orificemeter Flow over Notch Orifice and Mouth Piece Losses due to Friction in Pipe Line Losses in Pipe Fitting Impact of Jet on Vane Study of Pressure Measurement Pitot Tube Free Vortex Apparatus Technical Specifications of Hydraulic Bench Water Circulation 1 HP Pump, Crompton/ Kirloskar make. Flow Measurement: Using Measuring Tank, Capacity 40 Ltrs. Sump Tank Capacity Stop Watch Electronic. Control Panel Comprises of: Standard make On off Switch, Mains Indicator, etc. Instruction Manual: An English instruction manual will be provided along with the Apparatus Tanks and Top Tray will be made of Stainless Steel.

ORIFICE & JET VELOCITY APPARATUS

Specification: ORIFICE & JET VELOCITY APPARATUS In the Orifice & Free Jet Flow accessory a constant head tank is fed with water from the Hydraulics Bench. The orifice is installed at the base of this tank by means of a special wall fitting, which provides a flush inside surface. The head is maintained at a constant value by an adjustable over flow and is indicated by a level scale. A series of adjustable probes enable the path followed by the jet to be ascertained. Demonstration Capabilities:- Establishing the coefficient of velocity for a small orifice. Finding the coefficient of discharge for a small orifice with flow under constant head and flow under varying head. Comparing the measured trajectory of a jet with that predicted by simple theory of mechanics Establishing the coefficient of velocity for a small orifice Finding the coefficient of discharge for a small orifice with flow under constant head and flow under varying head Comparing the measured trajectory of a jet with that predicted by simple theory of mechanics Technical Specifications:- Orifice diameters: 3.0 mm and 6.0 mm Jet trajectory probes: 8 Max constant head: 410 mm

FLOW METER DEMONSTRATION

Specification: FLOW METER DEMONSTRATION The Flow Meter Demonstration Unit is a self-contained facility to demonstrate the important characteristics of flow meters. The main elements are a service module and flow meter support stand. A self-priming centrifugal pump draws water from the sump tank in the service module and delivers it to a flow meter test pipe. Industrial type flow meters mounted in test sections can be fitted into the test pipe quickly and easily. These meters have been chosen to give a variety of different metering principles and degrees of sophistication and accuracy. Some of the meters are calibrated directly in units of flow, whilst others involve the use of calibration charts. The pressure drop across each of the flow meters can be measured by using either the one meter pressurized water manometer or the 0.5 meter mercury manometer supplied. Ported manometer connection valves ensure rapid bleeding of all manometer pipe work. A facility exists to admit air into the hydraulic stream to demonstrate the effect on the meter™s accuracy. The discharge from the test section is controllable and is fed through a diffuser into the channel of the service module. Demonstration Capabilities:- Comparing the use application and limitations of various types of flow meter Considering the implications of flow meter selection on performance, accuracy, convenience, cost and head loss Understanding the principles on which different types of flow meter are based Relating pressure drop across a flow meter to flow rate Using manometers to measure pressure drop Investigating the effect of air in the hydraulic stream on flow meter performance Understanding the application of Bernoulli™s Theorem Technical Specifications:- Maximum flow rate: 2.3 liters/s Reservoir capacity: 140 liters Volumetric tank capacity: 40 liters Nominal bore of pipe work: 38mm Length of removable test pipe: 750mm Pump motor rating: 0.55kW A self-contained apparatus to demonstrate the characteristics of flow meters used in measurement of water flow through pipes or open channels Service module with reservoir, volumetric measuring tank and pump Reference turbine flow meter permanently fitted Metering devices available in various combinations to suit coursework

PITOT TUBE SET-UP

Specification: PITOT TUBE SET-UP A Pitot tube is used to measure the local velocity at a given point in the flow stress. A pitot tube of standard design made of copper/SS is supplied and is fixed below vernies scale. The vernies scale is capable to measure the position of Pitot tube in transparent section. The pipe has a flow control valve to regulate the flow. A U-tube manometer is provided to determine the velocity head. Present set-up is self-contained water re-circulating unit, provided with a sump tank and a centrifugal pump etc. Flow control valve and by-pass valve are fitted in water line to conduct the experiment on different flow rates. Flow rate of water is measured with the help of measuring tank and stop watch. Product Specification Phase: Single Phase Material: Stainless Steel Current: 5-15 amp Frequency: 50Hz Voltage: 220V AC Floor Area Required: 1.5 x 0.75 m

FLOW CHANNEL

Specification: FLOW CHANNEL The channel consists of a clear acrylic working section of large depth-to-width ratio incorporating undershot and overshot weirs at the inlet and discharge ends respectively. Water is fed to the streamlined channel entry via a stilling tank to reduce turbulence. Water discharging from the channel is collected in the volumetric tank of the Hydraulics Bench and returned to the sump for recirculation. A dye injection system incorporated at the inlet to the channel enables flow visualization in conjunction with a reticule on the rear face of the channel. Models supplied with the channel include broad and sharp-crested weirs, large and small-diameter cylinders and symmetrical and asymmetrical aerofoil™s, which in conjunction with the inlet and discharge weirs, permit a varied range of open channel and flow visualization demonstrations. Demonstration & Visualisation Capabilities:- Demonstrating basic phenomena associated with open channel flow Visualization of flow patterns over or around immersed object Technical Specifications:- Clear acrylic working section fed from stilling tank Six different models for investigation Dye injection system Quick release fitting for easy connection to Hydraulics Bench Educational software available as an option Dye injection needles: 5 Dye reservoir capacity: 0.45 L

HYDRAULIC RAM DEMONSTRATION

Specification: HYDRAULIC RAM DEMONSTRATION The Hydraulic Ram comprises an acrylic base incorporating pulse and non-return valves and a supply reservoir on a stand, which is fed by the Hydraulics Bench. An air vessel above the valve chamber smoothes cyclic fluctuations from the ram delivery the weights supplied may be applied to the pulse valve to change the closing pressure and thus the operating characteristics. Demonstration Capabilities:- Establishing flow/pressure characteristics and determining efficiency of the hydraulic ram. Technical Specifications:- Pump body manufactured from clear acrylic with stainless steel pulse and non-return valves. Adjustable acrylic header tank with inlet and outlet hoses. Outlet hose with variable head arrangement. Quick-release fitting for easy connection to Hydraulics Bench. Supplied with weights to load pulse valve. Educational software available as an option. Supply head: 300-700 mm variable. Delivery head: 750-1500 mm variable.

FRANCIS TURBINE DEMONSTRATION

Specification: FRANCIS TURBINE DEMONSTRATION Features Design and function of a Francis turbine Determination of torque, power and efficiency Graphical representation of characteristic curves for torque, power and efficiency Determination of mechanical output Determination of efficiency Recording of characteristic curves Investigation of the influence of the guide vane position on the power output Velocity triangles Specification Turbine Output: approx. 350W at 1500min-1, 270L/min, H=15m Max. Speed: 3000min-1, Rotor, 11 blades Medium diameter: 60mm, Distributor, 7 vanes Angle of attack: 020 Measuring ranges Torque: 09,81Nm Pressure: 04bar abs. Speed: 04000min DIMENSIONS AND WEIGHT L x W x H: 1000-x800 x 1200 mm Weight: 90kg

FREE & FORCED VORTEX APPARATUS.

Specification: FREE & FORCED VORTEX APPARATUS Free and Forced Vortex Flow apparatus offered by us has been painstakingly designed by our team of expert professionals. This apparatus enables the researchers to determine the shape of the vortex profile. With the accuracy of the results it provides, this apparatus is very popular in the market. Created using optimum quality materials and cutting edge technology, this delivers flawless performance. We subject it to quality tests based on multiple parameters before making it available to the customers. Range Of Experiments To visualize the forced & free vortex phenomenon. To plot the shape of vortex profile i.e. vertical height vs horizontal radius.

ORIFICE METER DISCHARGE

Specification: ORIFICE METER DISCHARGE The Orifice Discharge accessory consists of a cylindrical clear acrylic tank which has an orifice fitted in the base. A traverse assembly is provided which enables a piton tube to be positioned anywhere in the jet. Attached to this piton tube is a fine wire which can be traversed across the jet to accurately measure the jet diameter and the vena contract diameter and so determine the contraction coefficient. The piton head and the total head across the orifice are shown on manometer tubes adjacent to the tank. In addition to the sharp edged orifice six additional orifices with different profiles are supplied. All orifices have a common bore of 13 mm for direct comparison of performance. Demonstration Capabilities:- Determining the contraction and velocity coefficients Calculating the discharge coefficient Technical Specifications:- Cylindrical clear acrylic tank with orifice fitted in base Seven interchangeable orifices Piton tube and wire-on micrometer to measure jet velocity and diameter Quick-release fitting for easy connection to Hydraulics Bench Educational software available as an option Traverse mechanism: Lead screw with adjusting nut calibrated 0.1mm per division Standard orifice: Sharp-edged 13mm diameter Max head: 365mm

PELTON WHEEL TURBINE DEMONSTRATION

Specification: PELTON WHEEL TURBINE DEMONSTRATION This accessory comprises a miniature Pelton wheel with spear-valve arrangement mounted on a support frame, which fits on to the Hydraulics Bench top channel. Mechanical output from the turbine is absorbed using a simple friction dynamo meter. Pressure at the spear valve is indicated on a remote gauge. A non-contacting tachometer may be used to determine the speed of the Pelton wheel. Basic principles of the Pelton turbine may be demonstrated and, with appropriate measurements, power produced and efficiency may be determined. Demonstration Capabilities:- Determining the operating characteristics, ie power, efficiency and torque, of a Pelton turbine at various speeds Technical Specifications:- Turbine wheel inside cast housing with acrylic panel to enable viewing Mechanical torque measured using dynamometer with spring balances Inlet pressure gauge Quick-release fitting for easy connection to Hydraulics Bench Educational software available as an option Speed range: 0-2000 rpm Brake power: 10W Pressure gauge range: 0-25 m H2O Force balance range: 0-20 N x 0.2 N Number of Pelton buckets: 16 Diameter of Pelton wheel: 123 mm

METACENTRIC HEIGHT APPARATUS.

Specification: METACENTRIC HEIGHT APPARATUS Metacentric Height Apparatus Complete with Collecting Tank: Edutek For the purpose of providing the best Metacentric Height Apparatus to our clients, we use raw materials of the finest quality and strictly as per the set industrial standards, the quality standard never deteriorates. Made available in the market at a very competitive price, the offered product of impeccable functionality and efficiency, is one of the best available in the market. Technical Specifications: Pontoon: Size 300 x 300 mm (approx.) with a Horizontal Guide Bar for aliding weight and Removable Strips, Graduated arc with Pointer with moveable hanger And set of weights Water Tank: Size 550 x 500x 400 mm (approx.) Front Window of Tank: Made of Glass/Perspex A set of weights is supplied with the apparatus Instruction Manual: An ENGLISH instruction manual will be provided along with the Apparatus Tanks will be made of Stainless Steel Pendulum and graduated are for accurate measurement of Tilt angle

CENTRIFUGAL PUMP DEMONSTRATION

Specification: CENTRIFUGAL PUMP DEMONSTRATION The centrifugal pump is the machine most commonly used to move liquids from one place to another. As such it is a particularly instructive unit with which to introduce students to the whole subject of rot dynamic fluid machines. A motor driven centrifugal pump, mounted on a stainless steel plinth with a water reservoir and pipework for continuous circulation. The pump volute and the water reservoir are manufactured from clear acrylic for maximum visibility. Similarly the pipe runs are made from transparent PVC. Manually operated valves at the pump inlet and outlet allow control of the flow and also facilitate the study of suction effects. The pump volute has been designed so that the impeller can be easily accessed and replaced without tools. This is delivered with two impellers, one with forward curved blades and one with backward curved blades, allowing the students to investigate the effects of impeller characteristics. Electronic sensors measure the pump inlet pressure, the pump outlet pressure, the flow rate and the water temperature. Features:- Demonstration of a single-stage centrifugal water pump in operation. Measurement of inherent-speed pump performance, including production of characteristic curves: Pump total head Motor input power Impeller speed Overall total efficiency Introduction to pump speed laws. Investigation of impeller styles. Comparison of student calculations with computer results. Technical Specifications:- Max flow rate: 6 L/min typical Max head: 9.0 m Max pump speed: 1800 rpm Motor power rating: 180 W

FLOW VISUALIZATION (HELESHAW) APPARATUS

Specification: FLOW VISUALIZATION (HELESHAW) APPARATUS Heleshaw App. is used to demonstrate the flow pattern of liquid for variuos types of models such as Circular shape, Square shape, Triangular shape, aero foil shap. ..etc.,

STUDY OF PRESSURE MEASUREMENT

Specification: STUDY OF PRESSURE MEASUREMENT This is a board mounted model which demonstrates various types of pressure measurement devices used in common practice. The devices incorporated are: o Single well Manometer o Differential Manometer o Sensitive Manometer o Pressure Gauge o Vacuum Gauge These devices are coupled to suction and discharge piping of Hydraulic Bench Pump and a close circulation system is established, with this set up, the working and operating principle of the pressure measuring devices can be studied. Product Description Phase : Single Phase Usage/Application : Pressure Measurement Packaging Size : Box Voltage : 220 Volt Material : Stainless Steel Automation Type : Automatic

VENTURI-METER & ORIFICE METER

Specification: VENTURI-METER & ORIFICE METER Voltage: 220-240V Body Material: Mild Steel Measuring Tank: 32 Liters Throat Diameter: 16 mm Sump Tank: 100 Liters Orifice meter Material: Clear Acrylic Compatible to 1 Inch

REYNOLDS S APPARATUS

Specification: REYNOLDS™S APPARATUS It is manufactured at our unit by using highest quality materials under the guidance of the experts. This is extensively used to illustrate laminar, transitional and fully turbulent pipe flows. It also determines the conditions under which the flow occurs. Reynolds Apparatus can be availed by our customers at an economical price. Features: Accurate result Enhanced functional life Easy to use Product Specification Frequency: 50 Hz Voltage: 220 Volt Phase: Single Phase Current: 5-15 amp

DRAINAGE & SEEPAGE TANK APPARATUS

Specification: DRAINAGE & SEEPAGE TANK APPARATUS The present set-up is designed to study the flow through permeable media. This apparatus consists of a tank whose bed is made from Stainless Steel. The sides of the tanks are supported and sealed so that it allows free access to the interior. One side of the tank is of Toughened glass to give good scratch free visibility over a long period of use and minimum sight obstruction. Second side is of Stainless Steel and required pressure tapings are mounted on the same. The tank has two adjustable overflows close to the each end so that constant head of water can be maintained in each half of the tank. These may be lowered to a position close to the bed of the tank for some experiments to provide sub soil drainage. Present set-up is self-contained water circulating unit with sump tank, Pump, flow control valve etc. Product Specification Drainage or Seepage Tank: Length 1500 mm Width 100 mm Tank Base: Stainless Steel or Aluminum Front Side: Toughened Glass (Front Side) Back Side: Stainless Steel Sump Tank: Stainless Steel, Capacity 100 Ltrs. Pump: FHP Pump, Crompton Make.

MICHEL TILTING PAD BEARING APPARATUS

Specification: MICHEL TILTING PAD BEARING APPARATUS Edutek Our firm is offering Michell Tilting Pad Bearing Apparatus to our consumers. These are designed with utmost precision by our experienced professionals using ultra-modern machines and equipment. Before the final delivery, these products are stringently examined on various grounds by our quality analyzers to ensure their flawlessness. Available at a very low market rates

MOTORIZED GYROSCOPE APPARATUS

Specification: MOTORIZED GYROSCOPE APPARATUS Manufacturing done in compliance with the set industry norms and guidelines, the offered Motorised Gyroscope Apparatus has its quality highly standardized. The finest raw materials and modern machines applied in its making, give the product superior performance and a longer service life. In addition, the offered range is marked at the most reasonable rate possible. We are a prominent firm engaged in offering Motorized Gyroscope Apparatus. The product is provided with a stainless steel disc mounted on a horizontal shaft. The variable speed motor of the product is mounted on a trunnion frame having bearings in a yoke frame which freely rotates about its vertical axis. To maintain a proper balance, the apparatus is installed with a weight pan on the other side of the rotor disc which can be moved about three axis. Scope of Experimentation Observation of gyroscopic effect of rotating disc To study the gyroscopic effect of a rotating disc Experimental justification of the equation T = l w. wp for calculating the gyroscopic couple by observation and measurement of results for independent vibrations in applied couple T and precession wp Utilities Required 1m x 1m, 230 V AC, single phase Bench area Tachometer to find out RPM of disc Electric supply Technical Details Stop Watch, Electronic Variable speed of standard make Supplied with Speed Control Unit Weights: 2 kg, 1 kg, kg Stainless Steel Diameter: 300 mm x 12 mm thick precisely balanced which can be rotated in 3 mutually perpendicular axis Motor Accurately marked scale & pointer to measure precession rate Features: Easy to operate Accurate Longer service life

FLOCCULATION TEST RIG APPARATUS

Specification: FLOCCULATION TEST RIG APPARATUS Product Description We have emerged as a well-known firm that is involved in offering an extensive range of Flocculation Jar Test Apparatus. Besides, we provide our valued patrons with the entire series at market leading prices. Features: Longer service life Advanced technology used Low maintenance Excellent in performance Compact design Longer working life Description: Uniform Stirring of up to 6 samples simultaneously. Variable Speed “ 20 “ 100 RPM Heavy Duty Motor Stainless Steel paddles with adjustable heights. Spacing of 6 between rod permit uses up to 1000 ml Beaker. Power- 220/230 V AC, Single Phase 50 Hz

SLIP & CREEP MEASUREMENT APPARATUS

Specification: SLIP & CREEP MEASUREMENT APPARATUS We are engaged in offering a wide array of Slip and Creep Measurement Apparatus for measure co-efficient of friction between pulley material and different belt materials. To measure belt slip speed and observe the limited value of load constant speed when the slip just starts. The motor speed is varied by Thyristor Control D.C. Drive. A double channel digital speed indicator indicates driving and driven pulley speeds. With the help of Stroboscope (not in the scope of supply) it is possible to demonstrate the slip of belt on driving and driven pulley. Used in major experimental applications, this range is inclusive of very salient features. Scope of Experimentation: To measure co-efficient of friction between pulley material and different belt materials To measure power transmitted with varied belt tension To measure percentage slip at fixed belt tension by varying load on the Brake drum and plot the graph of v/s percentage slip i.e. Slip Characteristics Finding a Creep Zone from graph To measure belt slip speed and observe the limiting value of load at constant speed when the slip just starts To study creep of belt Utilities Required: Electricity: 0.5 kW, 220 V, Single Phase Stroboscope Technical Details: Motor Variable speed DC Motor 1HP, 1500 RPM Pulleys Driving and driven pulleys of equal diameters (flat pulleys) Loading Arrangement Brake drum along with spring balance and rope arrangement is provided to load the system Belts Flat belts of fixed length of following belt material like Fabric Belt, Canvas Belt, Leather Belt Belt tightening arrangement Bearing block is sliding and dead weight can be applied to set the initial tension in belt Speed Indicator 2 Channel digital speed indicator with switch to change the channel

CORIOLLIS COMPONENT OF ACCELERATION APPARATUS

Specification: CORIOLLIS COMPONENT OF ACCELERATION APPARATUS We are offering a wide range of Coriolis Component Acceleration. This entire set up is designed to study various coriollis components of a slider crank mechanism. In this process the continuous stream of water which is flowing through a steady rotating pair of tubes replaces mechanical slider system. The tubes of the system can be easily rotated in various speeds with the usage of a swinging field motor which also serves a dynamometer. There is a Perspex window located on the top of the tank. This window assures complete clear view of the process. It also prevents the splashing of water over the side of the tank. The in-built dynamometer continuously measures the torque which is applied to the various rotating tubes. This entire equipment is self-contained. The re-circulating of the water is assisted with a own speed control unit and water circulating pump which is separate. Experimentation To determine Coriolis Component of Acceleration at various speeds of rotation and water flow rates Utilities Required Electricity 0.5 kW, 220 V, Single Phase Drain Water Supply Technical Details: Swinging field type, variable speed Pump, FHP The whole set-up is well designed and arranged in a good quality painted structure Fabricated out of stainless steel Rotating arms 9mm/6mm orifice diameter, length 300 mm Rotameter, Electric motor, Main tank Control Panel comprises of: Speed control unit Standard make on/Off switch, mains indicator RPM indicator with proximity sensor RPM measurement

UNIVERSAL GOVERNOR APPARATUS

Specification: UNIVERSAL GOVERNOR APPARATUS We offer optimum quality Universal Governor Apparatus to our valuable customers. This universal governor apparatus offered by us is commonly used for studying the working of different governors that normally. The set-up is designed to study the working of different governors normally used to control the speed. It consists of a main spindle, mounted vertically on the base plate. This spindle is driven by a variable speed Motor which is also mounted vertically on the same base plate. Anyone governor assembly out of four can be mounted on spindle. Speed control unit controls the spindle speed. A graduated scale is fitted to the sleeve to measure the displacement. Experiments Determination of characteristic curve of a sleeve position against speed of rotation for all governors To study the effect of varying the mass of the center sleeve in Porter and Proell Governor To study the effect of varying the initial spring compression in Hartnell Governor To study the determination of characteristics curves of radius of rotation against controlling force (Actual & Theoretical) for all governors Utilities Required Power Supply: 230 V AC, Single Phase. Floor Space: 1.5 x 1.5 m Tachometer to find out RPM

SEDIMENTATION STUDIES APPARATUS

Specification: SEDIMENTATION STUDIES APPARATUS Our expertise in the field of manufacturing has helped us satisfy the expectations of our clients. The Sedimentation Studies are high quality equipment™s which are manufactured at our ultramodern infrastructure facility in compliance with the prevailing industrial standards. These are supplied to clients in different specifications at affordable market prices. Known for their sturdy designs and durable exterior, these equipment™s are highly demanded by chemical engineering laboratories. Descriptions of Sedimentation Studies Apparatus Settling or sedimentation is the separation of solid particles from fluids under the gravitational force. When a solid particle moves in a fluid. Then a number of forces are acting on it: o The gravitational force, acting downward. o The buoyant force, acting upward. o The drag force, acting upward. When a particle fall in a fluid under constant force, e.g. force of gravity, then particle accelerates for some time, but when the accelerating force equals the retarding force (Buoyant force and Drag force) then the resultant force acting on the particle will be zero, and particle quickly reaches velocity, which is the maximum attainable under the circumstances and which is called the terminal velocity. When slurry is prepared in a container and then allowed to remain undisturbed for some time, four settling zones will appear as below: A Supernatant Layer C Transition Zone B Slurry Zone D Concentration Sludge Zone. With the passage of time, the height of the different zones will vary and ultimately zone A of clear liquid and zone D of the sludge will be left. When all the solid particles settle in zone D, then this is critical stage and after this no settling takes place. With further passage of time, the height of the zone D will decrease due to the compression of the sludge on account of its own weight. Settling can be free settling or hindered settling. But most of the slurries settle under hindered conditions. Free settling is that in which the motion of one particle is unaffected by the motion of the other particle while in case of hindered settling many particles are present so there is mutual interference in the motion of the particles and the velocity of motion or rate of settling is reduced. The present set-up with 5 Nos. of Borosilicate Glass Graduated Cylinders is designed to study the zone settling depending upon the concentration and characteristics of the particles. These cylinders can be easily removed for cleaning. Rate of change in height of the various liquids/solids interfaces with respect to time can be measured with the help of stop watch. Experimentation of Sedimentation Studies Apparatus To determine Effect of initial concentration and initial suspension height on sedimentation rates. Effect of particle size distribution. Use of flocculating additives. Features: Reasonably priced Damage-resistant Efficient performance

DEEP BED FILTER COLUMN APPARATUS

Specification: DEEP BED FILTER COLUMN APPARATUS The present set-up is designed to study the characteristics of a filter column. It consists of a column filled with packing to ensure the good water distribution. 20 Slotted pressure tapings are mounted on the column for measuring the pressure drop across the bed per unit length. These tapings are connected to a differential manometer. These tapings can also be used for drawing the samples from the column and change in concentration of the suspension can be determined. The unit is complete with 2 Nos. of feed tanks. A centrifugal pump is provided to circulate the water through the column. Water supplied to the column is regulated and controlled by rotameter. Product Specification Water Circulation: FHP Pump Column Material: Stainless Steel/Perspex Column ID: 100 mm (approx.) Column Length: 1350 mm (approx.) Feed Tank Capacity: 200 Ltrs. (approx.) Flow Measurement: Rotameter for Water, 0.5 to 5 L/min. Pressure Tapings: 20 Nos. Sampling Ports: 20 Nos.

AERATION UNIT APPARATUS

Specification: AERATION UNIT APPARATUS The set-up consists of an open water tank with variable speed paddle mixer. Air is supplied to the water from the bottom and mixed in the water by operating stirrer. Speed of the stirrer can be controlled with the help of speed controlled provided in the Panel. Flow of air entering in the water tank is directly metered with the help of Rotameter and can be regulated by means of Valve provided in the set-up. Three air diffusers of different types are provided with the set-up and are interchangeable. Desired diffuser can be easily installed on the air inlet to the water tank. A Temperature Indicator is also provided which gives the direct reading of water temperature. The present set-up is complete in all respect to demonstrate the oxygen transfer characteristics of diffused air system. A battery powered Dissolved Oxygen Meter accompanies the apparatus which allows to conduct the experiment with ease Product Specification Capacity: 25 ltr Type: NA Power: 220V AC 1 PHASE Application: LAB EXPERIMENT Country of Origin: Made in India

PIN ON DISC WEAR APPARATUS

Specification: PIN ON DISC WEAR APPARATUS Conforms to ASTM standards. Measurement of wear, friction, co-efficient of friction & temperature Performs test under sliding wear conditions. Real time data acquisition of wear, friction, co-efficient of friction & temperature etc. Product Specification Material: Stainless Steel Frequency: 50 Hz Country of Origin: Made in India

JOURNAL BEARING APPARATUS

Specification: JOURNAL BEARING APPARATUS The apparatus consists of a plain steel shaft excavated in a bearing and directly driven by a FHP Motor. The bearing is freely supported on the shaft and sealed at the motor end. The speed of the motor is controlled accurately by the speed control unit and it can be made run in both directions. Twelve equal-spaced pressure taping around the circumference and four along the axis are provided and are connected to manometer by PU Tubing so that the pressure head of oil in all tubes can be observed at a time. The bearing can be loaded by attaching weights to the arm supported beneath it. Experiments To study the pressure profile of lubricating oil at various conditions of load and speed Plotting the Cartesian polar pressure curves To measure the frictional torque and power transmit Utilities Required Electric supply: 230 V AC, Single Phase. Bench area: 1.5 x 1.5 x 4 m Tachometer to find out RPM of journal Oil SAE 40 about 5 Ltrs.

AEROBIC DIGESTER APPARATUS

Specification: AEROBIC DIGESTER APPARATUS Aerobic Digester consists of a 2 gallon reactor vessel mounted on a steel base, with a liquid feed pump, air supply, and instrumentation for monitoring and controlling the process. The cylindrical wall of the reactor is made from 2 layers of porous plastic material to retain the suspended solids, while allowing treated water to pass through to the outer, annular exit chamber. This design allows the essential features of the aerobic treatment process to be studied without the distractions of having to settle the solids adequately enough for external recycle, a well-known laboratory problem. The porous liners are removable for cleaning, and a spare liner is supplied. Waste water is drawn from a feed tank by a 120V motor driven peristaltic pump. Flow rate is controlled by a variabe run time control that determines the minutes of run time within a 10 minute cycle. The pump delivers the feed to the reactor vessel through a transparent lid. Air is supplied at a measured rate by a small air pump, and discharges into the base of the reactor via an air distribution device. This provides the necessary oxygen for the digestion process, as well as produces sufficient bubbling for stirring and reaction. The liquid level in the reactor is maintained at a constant value of 1 or 2 gal. by an overflow device connected to the outer annular chamber of the vessel. Discharge is by gravity to a floor-standing product tank (not supplied). The reactor temperature is maintained by a 3-term PID controller which varies power to an immersion heater within the vessel. Any temperature between ambient and 95F may be selected, with the best conditions being a few degrees above the diurnal maximum in the user™s laboratory. Dissolved oxygen and pH probes and meters are included. The reactor lid contains a gas exit port, suitable for sampling the gases for subsequent analysis Feed pump 120V, peristaltic, 10 rpm, variable run time control corresponding to 0“13 gal. Per day Air pump 240V/120V, 0“1.35 gpm Reactor vessel 2 gal. maximum capacity pH meter Range 0.00 to 14.00 Dissolved oxygen meter Range 0“100% saturation, resolution 2%Reactor heater Electrical immersion 250WTemperature controller 3-term PID, temperature limit set at 95F

TRI-FILAR SUSPENSION SYSTEM

Specification: TRI-FILAR SUSPENSION SYSTEM A uniform circular disc is suspended from the pendulum support frame by three parallel cords. Top ends of the cords pass through the three small chucks fitted at the top. Other ends are secured in the Tri-Filer disc. It is possible to adjust the length of the cord by loosening the chuck. Learning Objectives/Experiments: To determine the radius of gyration of tri-filar suspension. Required for Operation: Floor Area: 0.5 x 0.5 m. Technical Specifications: Circular disc: dia. 300 mm approx. Weights: 250 gms (3nos.), 750 gms (3 nos.) The whole set-up is ingeniously designed and schematically arranged on a powder-coated rigid structure

MODEL SEDIMENTATION TANK

Specification: MODEL SEDIMENTATION TANK The apparatus is designed to demonstrate the hydraulic characteristics and settling efficiencies of a model settling basin. The apparatus consists of a Sedimentation Tank in which the water is fed by overhead tank (available in user laboratory and not in scope of supply) at constant flow rate and is measured with the help of a Rotameter. A complete unit for slurry circulation in sedimentation tank also accompanies the set-up including a sump tank for slurry, a feed pump for slurry. Flow rate of slurry entering the sedimentation tank is metered by suitable device. An accurate dye injection system is provided to inject the known volume of dye in the sedimentation tank. In sedimentation tank a weir is fitted which facilitate to the entry of well mixed slurry of known concentration in sedimentation tank uniformly. Product Specification Material: pvc/ss Type of Service Contract: Project Based Dimension: 6X4X5 FEET Usage/Application: LAB EXPERIMENT Current: 220V Cylinder: NA

EPICYCLE GEAR TRAIN APPARATUS

Specification: EPICYCLE GEAR TRAIN APPARATUS We are one of the leading manufacturers, suppliers, traders and exporters of optimum quality Epicyclic Gear Train Apparatus. This apparatus is manufactured from high quality raw material, which is procured from high known vendors. The quality controllers rigorously check the apparatus on the in-house quality check points Power Supply: 220 V AC, Single Phase Floor Area: 1.5 x 2 m Motor: Variable speed DC Motor, 1 HP

4 CYLINDER FOUR STROKE DIESEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER

Specification: 4 CYLINDER FOUR STROKE DIESEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER IC engines are widely used in automobile, domestic and industrial sector. They are classified according to cycle, number of cylinders, arrangement of cylinders, fuel used, type of ignition, valve arrangement, cooling system. Test rigs are used to find out the performance of an IC engine. It consists of an IC Engine, dynamometer, fuel measuring, air intake measuring and various other arrangements.

VCR 1 CYLINDER FOUR STROKE DUAL FUEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER

Specification: VCR 1 CYLINDER FOUR STROKE DUAL FUEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER/COMPUTERIZED VCR 1 CYLINDER FOUR STROKE DUAL FUEL ENGINE TEST RIG. The setup consists of single cylinder, four stroke engine connected to dynamometer for loading. It is provided with necessary instruments for combustion pressure and crank angle measurements. These signals are interfaced to computer through engine indicator for P?-PV diagrams. Provision is also made for interfacing airflow, fuel flow, temperatures and load measurement. The setup has standalone panel box consisting of air box, fuel tank, manometer, fuel measuring unit, transmitters for air and fuel flow measurements, process indicator and engine indicator. Rotameters are provided for cooling water and calorimeter water flow measurement.

CUT SECTIONAL MODEL OF ACTUAL 1 CYLINDER 2 STROKE PETROL ENGINE

Specification: CUT SECTIONAL MODEL OF ACTUAL 1 CYLINDER 2 STROKE PETROL ENGINE/CUT SECTIONAL MODEL OF ACTUAL 1 CYLINDER 4 STROKE PETROL ENGINE/CUT SECTIONAL MODEL OF ACTUAL 3 OR 4CYLINDER 4 STROKE PETROL ENGINE/CUT SECTIONAL MODEL OF ACTUAL 1 CYLINDER 4 STROKE DIESEL ENGINE/CUT SECTIONAL MODEL OF ACTUAL 4 CYLINDER 4 STROKE DIESEL ENGINE Cut Sectional Model Of Actual Single Cylinder Two Stroke Petrol Engine apparatus With Carburetor, spark plug etc. Complete with all salient parts sectioned for study of the various components and their function and to plot port-timing diagram on the single cylinder two-stroke petrol engine.

TWIN CYLINDER FOUR STROKE WATER COOLED DIESEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER

Specification: TWIN CYLINDER FOUR STROKE WATER COOLED DIESEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER/COMPUTERIZED TWIN CYLINDER FOUR STROKE WATER COOLED DIESEL ENGINE TEST RIG. IC engines are widely used in automobile, domestic and industrial sector. They are classified according to cycle, number of cylinders, arrangement of cylinders, fuel used, type of ignition, valve arrangement, cooling system. Test rigs are used to find out the performance of an IC engine. It consists of an IC Engine, dynamometer, fuel measuring, air intake measuring and various other arrangements.

SEPARATING & THROTTLING CALORIMETER APPARATUS

Specification: SEPARATING & THROTTLING CALORIMETER APPARATUS/ SEPARATING CALORIMETER APPARATUS/ THROTTLING CALORIMETER APPARATUS Description Separating Calorimeter: - It consists of two concentric chambers, the inner chamber and the outer chamber, which communicates with each other through an opening at the top. As the steam discharges through the metal basket, which has a large number of holes, the water particles due to their heavier momentum get separated from the steam and collect in the chamber. The comparatively dry steam in the inner chamber moves up and then down aging through the annular space between the two chambers and enters the Throttling Calorimeter. Throttling Calorimeter: - It consists a narrow throat (Orifice). Pressure and temperature are measured by pressure gauge and thermometer. The steam after throttling process passes through the heat exchanger and condensate is collected. Steam Generator is also provided to supply the saturated steam (Max.) at 2kg/cm2 pressure. Experimentation/Learning Objectives To find the dryness fraction of steam. Utilities Required Electric Supply: Single Phase, 220 V, 10 Amp. Continuous Water Supply: 10 LPM Approx. at kg/cm2 pressure Technical Details Separating Chamber: Compatible capacity made of Stainless Steel insulated with Ceramic wool with water level indicator. Throttling Chamber: Compatible capacity provided with gauge to measure inlet Pressure before throttling Heat Exchanger: For Condensing steam after throttling chamber Steam Generator: Compatible capacity with digital temperature controller to control the temperature inside the steam generator. Differential pressure: By manometer Measurement Steam pressure measurement: By Pressure gauge

CAM ANALYSIS APPARATUS

Specification: CAM ANALYSIS APPARATUS Edutek We are engaged in providing superior quality Cam Analysis Apparatus to our most reliable clients. These Cam Analysis Apparatus are appreciated by large number of clients due to high quality and durability. These products are available in market at most competitive rates. Descriptions Apparatus is a motorized unit consisting of a camshaft driven by a variable speed motor. The shaft runs in a double bearing. The free end of the camshaft has a facility to mount the cam easily. The follower is properly guided in gunmetal bushes and the type of follower can be changed according to the cam under test. Graduated circular protractor is fitted co-axial with the shaft. And a Dial Gauge fitted on the follower shaft is used to note the follower displacement for the angle of cam rotation. A spring is used to provide controlling force to the follower system. Weights on the follower shaft can be adjusted as per the requirement. An arrangement is provided to regulate the speed. The apparatus is very useful- for testing the cam performance for jump phenomenon during operation. On this apparatus the effect of change of inertia forces on jump action of earn-follower during operation can be observed. It is useful for testing various cam & follower pairs. Three cams and three followers will be supplied with the apparatus. These are already hardened to reduce the wear. Experiments With the help of combination of provided cams and followers following experiments can be conducted: To plot the n-Q (Follower displacement Vs Angle of rotation) curves for different cam follower pairs The follower bounce can be observed by using a stroboscope (Optional) & effect of follower weight on bounce can be studied. To study the effect of follower weight on bounce To study the effect of spring compression on bounce The tests can be repeated by changing compression springs, follower weights and cam speed. Utilities Required Electricity 0.5 kW, 220 V, Single Phase Stroboscope (Optional)

VCR 1 CYLINDER FOUR STROKE DIESEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER

Specification: VCR 1 CYLINDER FOUR STROKE DIESEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER/COMPUTERIZED VCR 1 CYLINDER FOUR STROKE DIESEL ENGINE TEST RIG. IC engines are widely used in automobile, domestic and industrial sector. They are classified according to cycle, number of cylinders, arrangement of cylinders, fuel used, type of ignition, valve arrangement, cooling system. Test rigs are used to find out the performance of an IC engine. It consists of an IC Engine, dynamometer, fuel measuring, air intake measuring and various other arrangements.

UNIVERSAL VIBRATION APPARATUS

Specification: UNIVERSAL VIBRATION APPARATUS We are engaged in the manufacturing and exporting of Universal Vibration Apparatus. To verify the relation of compound pendulum & to determine the radius of gyration. To study the forced vibration of simply supported beam for different damping. Descriptions The Universal Vibration apparatus provided comprehensive unit to perform the vibration experiments. A universal frame is provided upon which quick and easy assembly of various experiments can be done. The unit is self-contained to safely store spares. The students can easily assemble the experiments and study the theory of vibrations practically. Experimentation Following experiments can be performed with this unit: To verify the relation simple pendulum. To verify the relation of compound pendulum & to determine the radius of gyration. To study radius of gyration of bifilar suspension. To study the undamped free vibration of spring mass system. To study the longitudinal vibration of helical coiled spring. To study the damped torsional vibration of single rotor system and to determine the damping co-efficient. To study the forced vibration of simply supported beam for different damping. Undamped torsional vibrations of single rotor system. Undamped torsional vibrations of double rotor system. Verification of Dunker leys Rule.

1 CYLINDER FOUR STROKE DUAL FUEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER

Specification: 1 CYLINDER FOUR STROKE DUAL FUEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER The setup consists of single cylinder, four stroke engine connected to dynamometer for loading. It is provided with necessary instruments for combustion pressure and crank angle measurements. These signals are interfaced to computer through engine indicator for P?-PV diagrams. Provision is also made for interfacing airflow, fuel flow, temperatures and load measurement. The setup has standalone panel box consisting of air box, fuel tank, manometer, fuel measuring unit, transmitters for air and fuel flow measurements, process indicator and engine indicator. Rotameters are provided for cooling water and calorimeter water flow measurement.

STATIC & DYNAMIC BALANCING DEMONSTRATION

Specification: STATIC & DYNAMIC BALANCING DEMONSTRATION This equipment is designed for carrying out the experiment for balancing a rotation mass system. The apparatus consists of a steel shaft fixed in a rectangular frame. A set of four blocks with a clamping arrangement is provided. For static balancing, each block is individually clamped on shaft and its relative weight is found out using cord and container system in terms of number of steel balls. For dynamic balancing, a moment polygon is drawn using relative weights and angular and axial position of blocks is determined. The block is clamped on shaft is rotated by a motor to check dynamic balance of the system. The system is provided with angular and longitudinal scales and is suspended with chains for dynamic balancing. Experiments To balance the masses statically and dynamically of a single rotating mass system To observation of effect of unbalance in a rotating mass system Utilities Required Electricity 0.5kW, 220V, Single Phase

WHILING OF SHAFT DEMONSTRATION

Specification: WHILING OF SHAFT DEMONSTRATION The setup is designed to study the whirling of shafts. The set-up consists of a sturdy M.S. frame, variable speed motor bearing holders etc. Different bearing can be fitted in bearing block to have different end conditions i.e. (i) both end fixed, (ii) one end free and one end fixed etc. A variable speed motor is provided to drive the shaft along with speed control unit as the test is destructive, hence the shaft cannot be used again. Experiments Display of various modes of whril for a shaft with: Both ends directionally fixed. One ends fixed and other free Both ends directionally free. Modes of vibrations can be studied and frequency can be measured in each case. Utilities Required Floor area of 2m x 0.5 m Electric supply of 230V, AC

SPLIT AIR CONDITIONER TEST RIG

Specification: SPLIT AIR CONDITIONER TEST RIG Phase: Single Phase Voltage: 220V Material: Mild Steel Power: 1.25 KW Temperature Sensor: RTD PT-a hundred Kind Compressor: 1HP Current: 10 Amp

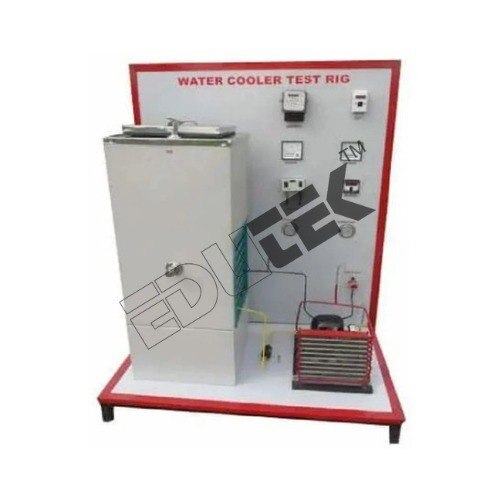

WATER COOLER TEST RIG

Specification: WATER COOLER TEST RIG We are engaged in the manufacturing, trading and exporting of superior quality Water Cooler Test Rig at a nominal market price. These products are manufactured under proper guidance using latest technology, advanced machinery and quality tested raw materials. Offered lab equipment is appreciated for their seamless finish, optimum performance and longer functional life. Cooling tower material: M.S. sheets Size: 200 X 200 mm. Height: 1.2m Water Heater power: 3 Kw capacity to provide hot water Centrifugal blower power: 1 HP to force air through tower Multichannel Digital Temperature Indicator to measure temperature at various points Rotameter to measure inlet water flow Measuring tank to measure outlet water flow Calibrated orifice and water manometer to measure air flow Arrangement to measure temperatures of water at five intermediate stations along the height of tower

AIR CONDITIONER TEST RIG

Specification: AIR CONDITIONER TEST RIG We offer exclusive quality Air Conditioning Trainer at the most affordable market price. These trainers are manufactured under the supervision of expert professionals using latest technology and quality tested raw materials. Appreciated for their hassle-free installation, sturdy construction, corrosion resistance and longer functional life, offered trainers are widely demanded by the clients. Specifications To study the vapor compression AC cycle To calculate COP To evaluate the tonnage capacity of the air conditioning system by enthalpy difference method. To evaluate actual and theoretical C.O.P. of the system. To plot the refrigeration cycle on P-H & T-S charts. To plot the psychometric processes on psychometric charts. To study the vapor compression AC cycle To calculate COP Utilities Required Stabilized power supply 15 Amp 220 V AC

WINDOW AIR CONDITIONER TEST RIG

Specification: WINDOW AIR CONDITIONER TEST RIG The model will be suitably sectioned to demonstrate the internal construction details showing the minute information, and working of the same, the model will be suitably painted and mounted on a metal or wooden base & supplied with key card & very interesting literature regarding working of the same. EXPERIMENTAL SETUP Compressor: Hermetically sealed compressor. Condenser: Air Cooled condenser made out of copper pipe & Aluminum fins of matching capacity with fan cooling. Evaporator: Fins and Copper tube type cooling coil of suitable capacity fitted in the unit Best Indian make. Expansion device: Thermostatic expansion valve. Energy Meter: For power measurement of compressor. Pressure Gauge: 2 Nos. for H.P., L.P. measurement Suitable filter/drier. Hand Shut Off type Service valve. Rotameter for Refrigerant flow measurement. MS Stand: The unit shall be assembled on heavy duty Angle Iron Base. Voltage: Single Phase 220 Volts 50 Hz. Ac Supply. Manual: Operation and maintenances manual should be provided along with the supplied equipment

AIR WASHER TEST RIG

Specification: AIR WASHER TEST RIG Air Washer Test Rig unit is required to conduct experiments and demonstrate the basic principal of psychometric properties of air. The test rig is designed for study of humidification of air. The unit is provided with all instruments and facilities to measure the temperature wherever required. The setup also provides the facility to conduct the experiment of heating and cooling of air and humidification. Experimentation/learning objectives: To study the cooling, humidification & dehumidification of air. To calculate the change in specific humidity of air. To calculate the change in temperature of air Utilities required: Electric supply: Single Phase, 220 V AC, 50 Hz. 32 Amp. MCB with earth connection. Earth voltage should be less than 5 volts. Water Supply: Initial fill. Floor Drain Required. Floor Area: 4.0 m x 1.5 m

3 OR 4 CYLINDER FOUR STROKE PETROL ENGINE TEST RIG WITH ROPE BRAKE/ ELECTRICAL BRAKE/HYDRAULIC BRAKE/ AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER

Specification: 3 OR 4 CYLINDER FOUR STROKE PETROL ENGINE TEST RIG WITH ROPE BRAKE/COMPUTERIZED 3 OR 4 CYLINDER FOUR STROKE PETROL ENGINE TEST RIG. Engine “ Automotive petrol engine. Four stroke four cylinder, water cooled, developing 20 BHP at 3000 RPM, provided with battery and self-starter. Rope Brake Dynamometer. OR suitable capacity hydraulic dynamometer also we can provide with electrical dynamometer. Measurements provided “ o Fuel intake measurement. o Air intake measurement. o Water circulated through engine jacket. o Water circulated exhaust gas calorimeter. o Digital Temperature Indicator for Exhaust gas & water temperature o Tachometer o Gauges for oil pressure & battery condition. o Arrangement to cut off the ignition to conduct morse test the test rig enables to determine I.H.P. B.H.P., specific fuel consumption, Air fuel ratio volumetric efficiency and heat balance sheet at different loads and speeds. A technical manual accompanies the unit.

1 CYLINDER FOUR STROKE WATER COOLED DIESEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER

Specification: 1 CYLINDER FOUR STROKE WATER COOLED DIESEL ENGINE TEST RIG WITH ROPE BRAKE/ELECTRICAL BRAKE/HYDRAULIC BRAKE/AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER/COMPUTERIZED 1 CYLINDER FOUR STROKE WATER COOLED DIESEL ENGINE TEST RIG. Description: The Test Rig consists of a vertical single cylinder water cooled compression ignition type diesel engine. It is coupled to a loading dynamometer, which in this case is Rope Brake Dynamometer. All the components are mounted on heavy duty M S channel. A desk type control panel consists of the following instrumentation: Digital RPM Indicator to measure the speed of the engine. Digital temperature indicator to measure various temperatures. Differential manometer to measure quantity of air sucked into cylinder. Burette with manifold to measure the rate of fuel consumed during test

AIR COOLER TEST RIG

Specification: AIR COOLER TEST RIG Air Cooler Test Rig unit is required to conduct experiments and demonstrate the basic principal of psychometric properties of air. The test rig is designed for study of cooling of air. The unit is provided with all instruments and facilities to measure the temperature wherever required. The setup provides the facility to conduct the experiment of cooling of air by temperature measurements.

1 CYLINDER TWO STROKE PETROL ENGINE TEST RIG WITH ROPE BRAKE/ ELECTRICAL BRAKE/HYDRAULIC BRAKE/ AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER

Specification: 1 CYLINDER TWO STROKE PETROL ENGINE TEST RIG WITH ROPE BRAKE/ ELECTRICAL BRAKE/HYDRAULIC BRAKE/ AIR COOLED EDDY CURRENT/WATER COOLED EDDY CURRENT DYNAMOMETER// COMPUTERIZED 1 CYLINDER TWO STROKE PETROL ENGINE TEST RIG. Ic Engines Are Widely Used in Automobile, Domestic and Industrial Sector. They Are Classified According to Cycle, Number of Cylinders, Arrangement of Cylinders, Fuel Used, Type Of Ignition, Valve Arrangement, Cooling System. Test Rigs Are Used To Find Out The Performance Of An Ic Engine. It Consists of An Ic Engine, Dynamometer, Fuel Measuring, Air Intake Measuring And Various Other Arrangements.

VAPOUR COMPRESSION CYCLE TRAINER APPARATUS

Specification: VAPOUR COMPRESSION CYCLE TRAINER APPARATUS The set up demonstrates the students about the basic principal of a refrigeration cycle. The test rig is designed for the study of thermodynamics of vapour Compression refrigeration cycle by way of demonstration and experimentation. It has a facility to measure various parameters for experimentation. Object:- To Study the Vapour Compression refrigerator cycle. To Calculate Co-efficient of performance Utilities required Electric supply: Single phase, 220 V AC, 50 Hz, 5-15 amp combined socket with earth connection. Earth voltage should be less than 5 volts. Water supply: 2LPM@1bar Floor drain required. Floor area: 1.5 m x 1 Technical detail: Compressor: Hermitically sealed compressor, reciprocating type. Capacity 1/3 Ton, Emerson Copeland make. Refrigerant: R-134-A Agitator: Compatible capacity. Condenser: Air cooled compatible to compressor Condenser Cooling Fan: Compatible capacity with permanent lubricated motor. Evaporator: Made of Stainless Steel, Insulated with ceramic wool/P.U.F. Rotameter: Make: Eureka, Range (6-60) LPH Expansion Device: Capillary Tube, Compatible Capacity. Pressure Gauges: 2 Nos. (For suction & discharge pressure) Safety Control: Overload and over current protectors for compressor and Time delay circuit with Low/high voltage auto-cut. Temperature Sensor: RTD PT-100 Type Control Panel comprises of: Digital Voltmeter: 0-500 V Digital Ammeter: 0-19.99Amp. Temperature Measurement: Digital Temperature Indicator with multi-channel switch. With mains indicator, Standard make On-off switch etc.

ICE PLANT TEST RIG