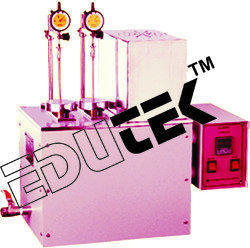

R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS

Product Details:

- Usage Engineering Testing Equipment

- Application Engineering Testing Equipment

- Product Type R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS

- Click to View more

R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS Price And Quantity

- 500 INR/Piece

- 1 Piece

R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS Product Specifications

- R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS

- Engineering Testing Equipment

- Engineering Testing Equipment

R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS Trade Information

- Carton Box, Export Quality also Available

- Asia Middle East Africa

- All India

- ISO 9001, 14001, CE

Product Description

Specification:

R.T.D. STUDIES IN PACKED BED REACTOR APPARATUS

Axial diffusion and dispersion offluid in packed beds are important for design and operation of separationequipment and Chemicals reactors. The tracer technique, the most widely usedmethod for the study of axial dispersion.

In stimulus response experimentation,we perturb the system using pulse input of tracer and then see how the systemreacts or responds to this stimulus.

The analysis of the response givesthe desired information about the system. The setup consists of a glass columnpacked with Rasching Rings and one feed tank. Water is fed to the reactorthrough liquid distributor, fitted at the bottom of the column.

Rotameter is provided to measure theflow of water. The flow rate can be adjusted by operating the needle valveprovided on Rotameter. For understanding the R.T.D. characteristics, a specialarrangement to inject tracer into the lower end of reactor, using a syringe, isprovided. Samples can be taken periodically from the top outlet of reactor.Pressure Regulator & Pressure Gauge are fitted in the compressed air line.

Experimentation/Learning Objectives

To plot RTD curve for Packed BedReactor.

To determine the Dispersion No.

Utilities Required

Compressed Air Supply: 0.25 CFM@1 bar

Water Supply.

Floor Drain.

Floor Area Required: 1.0 m x 1.0 m.

Instruments, Laboratory Glassware andChemicals required for analysis as per the system adopted.

Technical Details

Reactor Column: Material Borosilicate Glass

Packing: Rasching Rings, Material Borosilicate Glass. Size 8-10mm(approx.)

Feed Tank: Material Stainless Steel, Capacity 20 Ltrs.

Feed Circulation: By compressed air.

Flow Measurement: Rotameter.

Piping: Stainless Steel and PU pipe.

Pressure Regulator: 0-2 Kg/cm2

Pressure Gauge: Bourdon type 0-2 Kg/cm2

Stop Watch: Electronic

Arrangement is done to inject tracerinto the lower end of reactor

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Engineering Testing Equipment' category

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |