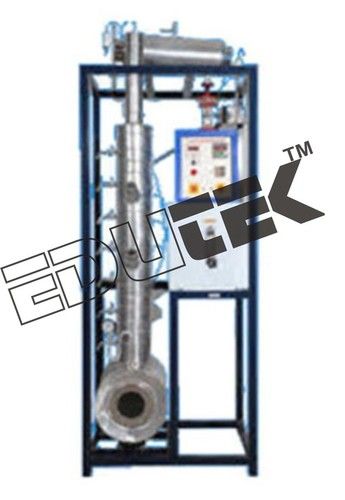

Solid and Liquid Extraction Unit

Product Details:

X

Product Description

Solid and Liquid Extraction UnitThe fundamental principle of solid-liquid extraction Unit can be learned with The temperature of the solvent can be adjusted. Thus, it is possible to investigate the effect of this parameter on the separation process.

This is a semi-batch unit designed for solid-liquid extraction as a means of separation.

The solid to be extracted is put inside a glass fibre bag and is placed in the extraction vessel. Solvent in the reactor is boiled and condensed, and passed to the

extraction vessel, from where extract is mixed with solvent and passes to the reboiler. The process is repeated until extraction is complete. Solution is again evaporated to obtain the extract.

The unit is complete with spherical vessel, heating bath condenser, reflux divider, extraction vessel, and necessary pipelines and valves.

The unit can be supplied with solvent feed either from the top/or bottom, or with common arrangement.

The principle of counter current in solid-liquid extraction :

- Extract outlet.

- Extraction residue.

- Extractant inflow.

- Extraction material inflow.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Mass Transfer Lab Equipments ' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |