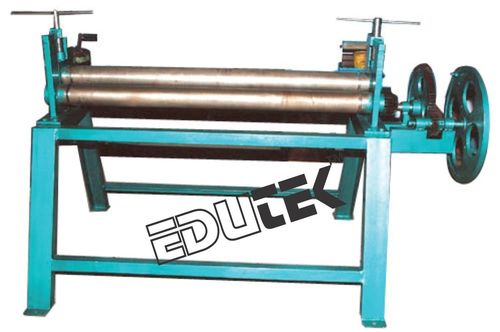

Bending Machine

Product Details:

X

Product Description

BENDING MACHINE

Specification:

- Nominal pressure = 2500 kn.

- Working table length = 3200 mm.

- Working table width = 280 mm.

- Throat depth = 320 mm.

- Distance between column = 2700 mm.

- Slide stroke = 250 mm.

- Opening height = 520 mm.

- Slide block speed: Rapid Down = 50 mm.

- Slide block speed: Load Speed = 7 mm.

- Slide block speed: Return = 40 mm.

- Overall Dimension (LxWxH) = 3400x1700x2800 mm.

- Main motor power = 15 kw.

- Max. sheet thickness = 6 mm.

- Major Elements = Digital readout.

- Electrics: Siemens.

- Main Motor: ICE standard.

- Oil pump: ICE standard.

- Sealing, blade and other mechanical components: standardized too.

- Installing environment = power: 380 Volt, and 50 Hz.

- Operation temperature: 0 to 40oC.

- Operation environment: Clean without dust.

- Main structure and performance = Designed hydraulic press brake technical conditions hydraulic press brake

- Accuracy, ensuring the structural strength and stiffness of each component.

- Overall steel plate welded structure, thick frame, high rigidity, shock absorption.

- Mechanical structure of the machine includes frame, working table, slider, main cy-linders and back gauge and other components,

- Dynamic bending design, smooth working, easy operation and safe,

- The frame and sliders and working table and other main parts should be machined to ensure the geometric accuracy of the machine, The guide of machines should have advanced selflubricating material, with no need to regular lubrication sti/min.

- Hydraulic system = Hydraulic system need to have all appropriate valves,

- Main motors ICE standard,

- Clear and intuitive height of the oil level and oil temperature display,

- The machine work continuously under rated loading, no leaking in hydraulic system, steady, high precision.

- Electric system = Portable foot

- Ball switch, with emergency stop function; Slider synchronization control = Adopts torsion bar synchronization control.

- Table deflection compensation=Mechanical deflection compensation mechanism,

- compensation workbench deformation, distortion compensation table according to the load of machine deflection;

- Display devices: = bending machine for digital devices;

- After the backgauge clearance prompt-ed a one-way; X / Y axis lead screw pitch error compensation ; Soft limit function; Time relay function ;

- Counting function- Technical Specifications Axis Parameter: X Axis and Y Axis travel range 0 to 9999.99 mm; X Axis and Y Axis display accuracy 0.1 mm.

- Encoder specifications: 50 KHz Count Frequency; Input Voltage: DC 12 V +- 4 % ; Maximum current: 200 mmp;

- Documents with machine = Operation manual (with hydraulic principle picture, electrical principle picture, and the foundation picture of machine tool);

Enter Buying Requirement Details

Other Products in 'Mechanical Engineering Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |