DOUBLE STAGE AIR COMPRESSOR TEST RIG

Product Details:

- Product Type DOUBLE STAGE AIR COMPRESSOR TEST RIG

- Usage Fluid Mechanics Lab Equipment

- Application Fluid Mechanics Lab Equipment

- Click to View more

DOUBLE STAGE AIR COMPRESSOR TEST RIG Price And Quantity

- 500 INR/Piece

- 1 Piece

DOUBLE STAGE AIR COMPRESSOR TEST RIG Product Specifications

- Fluid Mechanics Lab Equipment

- DOUBLE STAGE AIR COMPRESSOR TEST RIG

- Fluid Mechanics Lab Equipment

DOUBLE STAGE AIR COMPRESSOR TEST RIG Trade Information

- Cash on Delivery (COD) Cash Advance (CA) Cheque Telegraphic Transfer (T/T) Letter of Credit (L/C)

- Carton Box, Export Quality also Available

- Asia Middle East Africa

- All India

- ISO 9001, 14001, CE

Product Description

Specification:

DOUBLE STAGE AIR COMPRESSOR TEST RIG

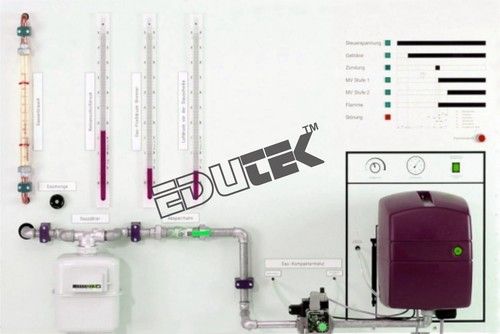

The present set-up is designed tostudy the Double Stage Air compressor. The set-up consists of a double stagereciprocating type air compressor. It is driven by a motor through a belt andpulley system. The drive motor is swinging field type and supplied with dialtype spring balance which permits direct torque measurement.

This arrangement facilitates the enduser to calculate the power transmitted by the motor to the compressor,accurately. To calculate input power to the motor, an energy meter is providedand in this way, by knowing the input and output, efficiency of the compressoris calculated easily. The outlet of the air compressor is connected to airreservoir and suction is connected to another air manifold tank.

The compressor draws air from thismanifold tank which is provided with bellow at one side. This tank also has anorifice with manometer to observe and calculate the air flow rate. Thecompressed air from the outlet side of the compressor is stored in providedreservoir. The reservoir is equipped with Pressure Gauge, Control Valve, SafetyValve, Drain etc. A water cooled intercooler for air, in between both head, isprovided to cool the hot and compressed air before entering the second stage.

Temperature of inlet air, aftersingle compression, inlet and outlet of second compression and pressure inreservoir and at intermediate stage can be measured by Temp. Sensors andpressure gauges.

Product Specification

Compressor: Double Stage, Double Cylinder, Capacity 6.9 CFM max. WorkingPressure Max. 7 kg/cm2

Drive: 2 HP, Crompton/Standard make,Swinging Field type.

Spring Balance: Dial type, 10 kg.

Flow Measurement: Orifice meter with Manometer

Temperature Measurement: RTD PT-100 type sensor (4Nos.)

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Fluid Mechanics Lab Equipment' category

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |