Experiments With An Axial Fan

Product Details:

X

Product Description

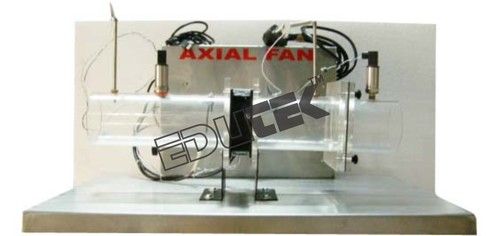

EXPERIMENTS WITH AN AXIAL FAN

Axial fans are used to transport gases. The medium to be transported is drawn in axially to the drive shaft of the axial fan by the rotation of the rotor. The medium flows through the rotor and is discharged axially behind the rotor.

The experimental unit provides the basic experiments to get to know the operating behaviour and the important characteristic variables of axial fans.

features an axial fan with variable speed via an integrated controller, an intake pipe and a delivery pipe. The transparent intake and delivery pipes are fitted with guide plates for flow guidance. A flow straightener in the intake pipe serves to calm the air. This enables precise measurements even with heavily reduced operation. The air flow is adjusted by a throttle valve at the end of the delivery pipe.

The experimental unit is fitted with sensors for pressure and temperature. The flow rate is determinated via differential pressure measurement on the intake nozzle.

The microprocessor-based measuring technique is well protected in the housing. All the advantages of software-supported experiments and evaluation are offered by the software and the microprocessor. The connection to a PC is made by USB.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Learning Objectives / Experiments

- Operating behaviour and characteristic variables of an axial fan

- Recording the fan characteristic (differential pressure as a function of the flow rate)

- Effect of the rotor speed on the pressure

- effect of the rotor speed on the flow rate stall

- determination of hydraulical power output and efficiencies

Specification

- functioning and operating behaviour of an axial fan

- Axial fan with electronically commutated drive motor

- Variable speed via integrated controller

- Transparent intake and delivery pipes

- Throttle valve to adjust the air flow in the delivery pipe

- Determination of flow rate via intake nozzle

- Display of differential pressure, flow rate, speed, electrical power consumption and hydraulical power output, temperature and efficiency

- Microprocessor-based measuring technique

- Unit-specific software for data acquisition and operation via USB under Windows Vista or Windows 7

Technical Data

Intake pipe

- Inner diameter: 110mm

- Length: 275mm

Delivery pipe

- Inner diameter: 110mm

- Length: 310mm

Axial fan

- Power consumption: 90W

- Nominal speed: 9500min-1

- Max. volumetric flow rate: approx. 600m³/h

- Max. pressure difference: approx. 700Pa

Displayed / measuring ranges

- Differential pressure: 0...1800Pa

- Flow rate: 0...1000m³/h

- Temperature: 0...100°C

- Speed: 0...3000min-1

- Electrical power consumption: 0...500W

Dimensions and Weight

- LxWxH: 680x360x380mm

- Weight: approx. 18kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |