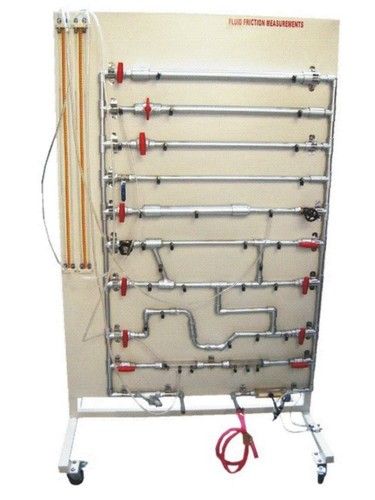

FLUID FRICTION MESURMENTS

Product Details:

X

Product Description

FLUID FRICTION MEASUREMENTS

Specification:

- System is mounted on a supporting rigid structure mounted on wheels.

- The flow velocity is measured using Floor Mount Type Parallel Pipes 'T'& 'Y' Junctions Fluid Mechanics: Friction Loss in Pipes Apparatus the calibrated variable area flow meter and the measuring tank of the Hydraulic Bench.

- The head loss due to friction should be measured using a suitably placed static pressure tapings, multi-tube manometer and digital pressure meter.

- Flow velocity or Reynolds number can be varied.

- A system of parallel pipe network configuration and isolating valves enable tests to be conducted on different pipes without disconnecting or draining the system.

Experiments:

- Familiarization and training with pressure and fluid flow measurements.

- Study of pipe friction at various flow velocities.

- Study of pipe friction in laminar and turbulent flows.

- Study of effect of surface roughness on friction factor.

- Determination of relationship between pipe friction factor and flow Reynolds numbers.

- Comparison of measured friction factors with Moody's chart.

Specifications:

The Apparatus should include the following pipes for testing:

- Smooth bore pipes: 27, 14 and 3.5 mm bore, 1800mm length, PVC.

- Artificially roughened pipes, 23 and 17 mm bore, 1800mm length, PVC. Color coding for piping system will be selected to suit user requirements.

- Pressure tapping is by small ball valves with quick connections will be provided at inlet and exit. Pressures are measured using multi-tube manometer. Pressure taps are connected to a set of manifolds by flexible pressure hoses such that differential pressure across pipe length can be measured by opening valves without removing the hoses.

- Flow measurement using Variable Area Flow Meter and measurement tank of the Hydraulic Bench.

- Water Manometer with hand air pump, 8 tubes X 800 mm with 1mm reading.

- Mercury Manometer, 2 tubes X 500 mm with 1mm reading.

- Digital Pressure Meter.

- Electrical supply, 240 V, single-phase, 50 Hz.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Building And Civil Engineering Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |