Fluid Mechanics Trainer

Product Details:

X

Product Description

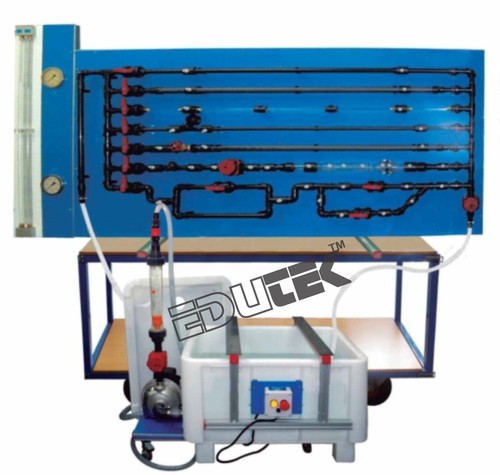

FLUID MECHANICS TRAINER

The knowledge of flow in pipe systems has a wide range of practical applications in many fields. When water flows through a pipe system the internal friction and the pipe friction cause pressure losses. The pressure losses in the fluid are directly dependent on the resistances and the flow velocity.

The trainer allows a variety of experiments for flow and pressure measurement and the determination of pressure losses and pressure curves in different pipe elements.

The trainer contains six different, horizontally arranged pipe sections, which allow the effects of pipe material, diameter and changes in cross-sectional and direction on the pressure loss to be studied. Measuring objects such as valves, strainers, a Venturi

nozzle, a Pitot tube or orifice plate flow meter or measuring nozzle can be used in another pipe section. To make the functions clearly visible, some of the measuring objects are transparent. Additional measuring objects are available as a set to expand the scope of experiments.

The trainer can be operated independently from the mains water network and is equipped with a pump and a water tank. The trainer includes a rotameter to determine the flow rate. Pressure measuring points are located immediately upstream and downstream of the measuring objects. These are designed as annular chambers, ensuring a precise pressure measurement. Five different pressure gauges with analogue or digital displays are provided for pressure measurement.

Depending on the measurement method, the measured values can be read off the analogue manometer or digital displays. The measured values are transmitted directly to a PC via USB.

Learning Objectives / Experiments

- Flow and pressure measurement methods

- Function of nozzle, orifice, Venturi nozzle

- Losses due to pipe bends and pipe angles,

- Changes in cross-section and shut-off valves and fittings

- Determining pipe friction factors and resistance coefficients

- Opening characteristics in shut-off valves and fittings

Specification:

- Trainer for fluid mechanics experiments

- Interchangeable measuring objects, partly transparent: angle seat valve, diaphragm valve, ball valve, non-return valve, strainer, Pitot tube, Venturi nozzle, orifice plate flow meter and measuring nozzle

- Different pipe sections

- Annular chambers allow precise measurement of pressure

- Tube manometer for measuring the differential pressure

- Flow measurement using rotameter

- Digital displays for pressure and differential pressure

- Software for data acquisition via USB under Windows Vista or Windows 7

- Additional set of measuring objects

Technical Data:

- Pump

- Power consumption: 0,68kW

- Max. flow rate: 7,2m³/h

- Max. head: 22,8m

- Storage tank: 55 L

Pipe section for interchangeable measuring objects:

- 32x1,8mm, PVC

- 3 straight pipe sections, length: 1000 mm

- ½", St, galvanised

- 18x1 mm, Cu

- 20 x 1,5 mm, PVC

Pipe section, PVC:

- Gradual contraction, diameter: 20x1,5-16x1,2mm

- Gradual enlargement, diameter: 20 x 1,5-32 x 1,8 mm

- With 90° pipe angle/ pipe bend,

- Diameter: 20x1,5mm

- Tube manometer: 2 x 2 tubes, 1 x 6 tubes

Measuring ranges:

- Differential pressure: 0...200mbar

- Pressure: 6x 0...600mbar

- Flow rate: 0,4...4m³/h

- Temperature: 0...60°C

Dimensions and Weight:

- LxWxH: 2450x900x2250mm

- Weight: approx. 280kg

Enter Buying Requirement Details

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |