X

Product Description

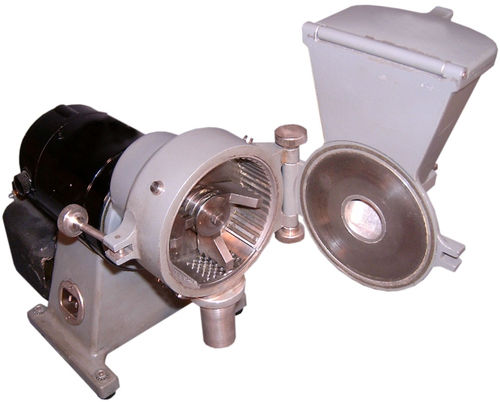

HAMMER MILL

ETP-211: Hammer mill is a economical unit designed for general all-round work for time saving operation. Most often, the only changes necessary are of Screens, hammers and liners. Feed Material passes through a wide feed hopper into the grinding chamber. The swinging hammers, in the rotating hammer rotor, crush materials at the stationery liners before driving them trough a screen and type of hammers used. The method of operation is impact grinding.

Combination of different hammer styles, liner plates, sieve inserts and wear resistance technology offer almost unlimited possibilities of crushing lumpy, bulky, irregularly shaped, hard & fibrous materials, into coarse to medium fine powder.

Machine to work on 220V AC 50 Hz single phase.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Pharmaceutical Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |