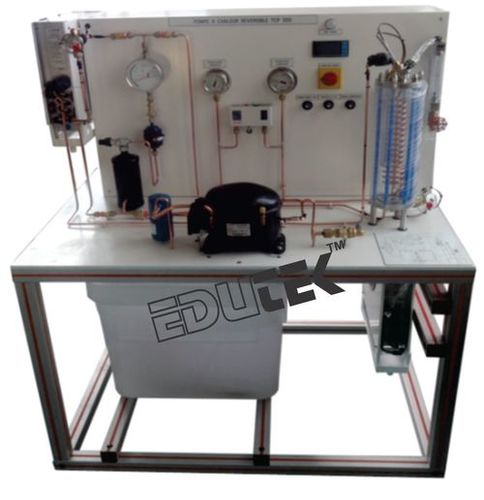

Heat Pump For Cooling And Heating

Product Details:

X

Product Description

HEAT PUMP FOR COOLING AND HEATING OPERATION

Refrigeration systems and heat pumps only differ in the definition of their use, but can be of the same design. For example, goods can be refrigerated in a supermarket and the store heated with the waste heat. The store can also be cooled with the same system in the summer.

With the cooling and heating operation can be investigated. Different operating modes can be selected via solenoid valves. Thus the glycol-water mixture in the tank can be heated or cooled. In pure cooling operation (without heating function) the heat exchanger with fan as air-cooled condenser dissipates the heat. This heat exchanger can be also switched as an evaporator.

The measured values are read from digital displays and can at the same time be transmitted via USB directly to a PC where they can be analysed using the software included. The software enables a clear representation of the process.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.The unit shall perform the following experiments and investigations:

Learning Objectives / Experiments

- Design, operation and key components of a heat pump or refrigeration system

- Depresentation of the thermodynamic cycle in the log p-h diagram

- Comparing different operating modes

- Measurement of compressor capacity and heating or cooling Capacity in the glycol-water circuit

- Determination of efficiency

- Coefficient of performance of heat pump and refrigeration system

- Specific compressor load

- Compressor pressure ratio

- Specific cooling capacity

- Specific refrigeration capacity

- Comparing key figures of heat pump and

- Refrigeration system

Specification

- Air-to-water heat pump for cooling or heating operation

- Different operating modes selectable via solenoid valves

- Refrigeration circuit with compressor, condenser (heat exchanger with fan), 2 evaporators with fan (refrigeration and freezing stage)

- glycol-water circuit with tank, pump and coaxial coil heat exchanger

- Coaxial coil heat exchanger and heat exchanger with fan can both be used as condenser or evaporator in the refrigeration circuit

- 1 thermostatic expansion valve each for all heat exchangers and evaporators

- 1 additional evaporation pressure controller and 1 capillary tube for the refrigeration stage evaporator

- Displays for temperature, pressure, flow rate and power consumption of the compressor

- Software for data acquisition with USB under Windows Vista or Windows 7

- Refrigerant R134a, CFC-free

Technical Data

- Compressor

- Refrigeration capacity: 934W at -6,7/55°C

- Power consumption: 620W at -6,7/55°C

- Heat exchanger with fan

- Transfer area: 1,25m², volumetric air flow

- Rate: 650m³/h, capacity: 1148W at DT=15K

- Evaporators with fan

- Refrigeration stage

- transfer area: 1,21m², volumetric air flow

- rate: 80m³/h, capacity: 140W (tL1=5°C, DT1=10K)

- freezing stage

- transfer area: 3,62m², volumetric air flow

- rate: 125m³/h, capacity: 330W (tL1=5°C, DT1=10K)

- Coaxial coil heat exchanger

- capacity: 1,6kW at 0°C; DT=9K

Measuring ranges

- Temperature: 11x -50...150°C

- Pressure: 2x -1...15bar, 1x -1...24bar

- Flow rate (refrigerant): 1x 4...40L/h

- Flow rate (glycol-water): 1x 2,5...65g/s

- Power: 0...1150W

Dimensions and Weight

- LxWxH: 2210x800x1900mm

- Weight: approx. 330kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

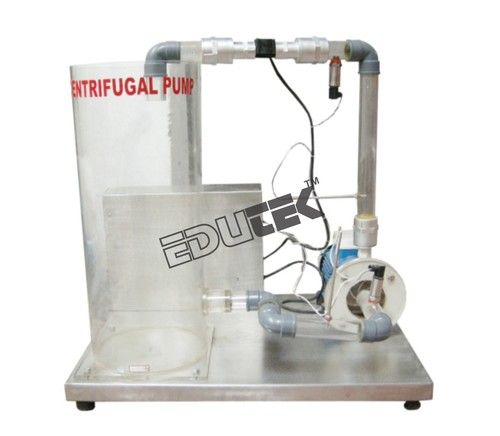

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |