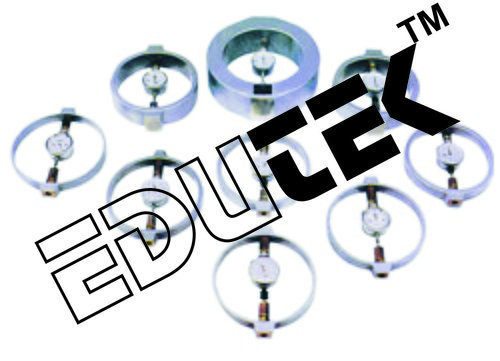

Integral Proving Rings

Product Details:

X

Product Description

Integral Proving Rings

The Proving rings are made of special steel carefully forged to give maximum strength and machined to give high sensitivity commensurate with stability ensuring long life and accuracy. All proving rings are integral type viz, the loading (outside) bosses are forged integral with the ring body. This ensures that there is no possibility of abutment shift and consequent loss of accuracy in reading that always exists with bolted abutments. The dial gauge and anvil are mounted on U-brackets clamped to the ring body by set screw. The dial gauge is fitted with a special back cover and threaded bush. Which does not permit any shift from the original dial alignment, coaxial with the loading boss centres, that is set at the factory before calibration. For all compression proving rings and tension compression proving rings up to and including 5 KN capacity the loading bosses have female threading BSP The boss faces are ground and polished and are plane parallel to within 0.2mm total DTI run out.

Tension compression rings have their integral loading bosses male threaded, 1.25 dia, 8 tpi square thread, 1.25 long. Caps are provided for use when loading in compression Repeatability is as stipulated in IS 4169 The rings are supplied complete with dial gauge and Works calibration Chart. Individuallypacked in polished wooden. Boxes. NCCBM Calibration can also be arranged for any proving ring at an additional cost. Proving rings to meet special requirements are also available on request. Separate polished and ground pair of Loading Pads FOR Compression Proving Rings and Pair of Shackles for Tension Proving Rings are provided to suit each proving ring, at extra cost.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Soil Testing Equipments' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |