Losses In Pipe Bends

Product Details:

X

Product Description

LOSSES IN PIPE BENDS

In addition to pressure losses due to pipe friction, pipes through which water flows experience pressure losses at changes in pipe direction. In practice, various changes in pipe direction with different geometries are used in pipe networks.

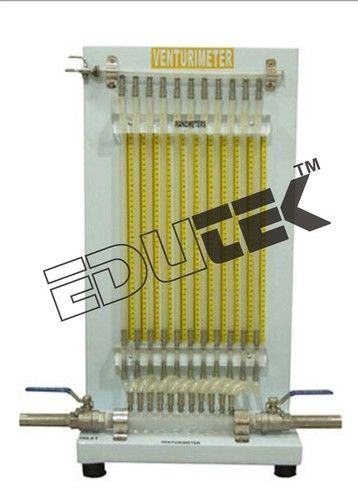

Used to investigate how different changes in pipe direction made from different materials affect the pipe flow. The pipe elements used are commercially standard components in heating and sanitary engineering. The clear panel is mounted on a sturdy, movable frame.

The trainer consists of four pipe elements with ten deflections each with the same pipe length. Two measuring sections have different radii and are made of different materials. A hose connects the desired measuring section. The flow is adjusted using valves in the inflow and return and read on a rotameter.

The pressure measuring points in the pipe system are designed as annular chambers and are located between the beginning and end of the measuring sections, ensuring a precise pressure measurement. The sensors are connected in pairs to a differential pressure meter and the respective differential pressure read on the display.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Learning Objectives / Experiments

- Flow measurement

- Differential pressure measurement

- Effect of flow and surface roughness

- Effect of the flow velocity

- Effect of changes in pipe direction

Specification

- Investigation of the pressure loss at pipe elements with different changes in pipe direction and materials

- Pipe elements are commercially standard components in heating and sanitary engineering

- Clear panel mounted on a sturdy, movable frame

- Simply selection of the measuring sections via hose connection with quick-release couplings

- Flow can be adjusted via valves

- Flow measurement using rotameter

- Differential pressure measurement via differential pressure meter with display

Technical Data

- Measuring sections: 2300mm

- Pipe section 1: steel, diameter: ½", 90° pipe angle

- Pipe section 2: steel, diameter: ½", 90° pipe bend

- Pipe section 3: copper, diameter: 18x1mm, 90° pipe angle

- Pipe section 4: copper, diameter: 18x1mm, 90° pipe bend

- Differential pressure meter

Measuring ranges

- Flow rate: 150...1600L/h

- Differential pressure: -350mbar...350mbar

Dimensions and Weight

- LxWxH: 1650x700x1850mm

- Weight: approx. 100kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |