Pelton Turbine

Product Details:

X

Product Description

PELTON TURBINE

The Pelton turbine is a type of free-jet resp. impulse turbine which convert the pressure energy of water into kinetic energy entirely in the distributor. Pelton turbines are used at large heads and relatively low flow rates. The turbine power is adjusted by means of the nozzle cross-section. In practice, Pelton turbines are used for driving synchronous generators, where they run at constant speed.

The Pelton turbine is an accessory for the trainer. The experimental unit consists of the Pelton wheel, a needle nozzle used as distributor, a band brake for loading the turbine and a housing with a transparent front panel. The transparent cover enables you to observe the water flow, the Pelton wheel and the nozzle during operation. You can change the nozzle cross-section and thus the flow rate by adjusting the nozzle needle.

The pressure at the turbine inlet is recorded with a pressure sensor. A force sensor and a speed sensor are attached to the band brake. Thus, the mechanical power output of the turbine can be determined. Speed, torque and pressure are displayed on the switch cabinet of and processed further in the software. Water supply and flow rate measurement are provided by .

The well-structured instructional material sets out the fundamentals and provides a step-bystep guide through the experiments.

- The unit shall perform the following experiments and investigations:

- Learning Objectives / Experiments

- Determination of mechanical output

- Determination of efficiency

- Rrecording of characteristic curves

- Investigation of the influence of the nozzle cross-section on the power output

Specification:

- Recording the curves of a Pelton turbine and investigating the influence of the nozzle crosssection

- Transparent front panel for observing the operating area

- Loading the turbine by use of a band brake

- Adjustable nozzle needle for setting different nozzle cross-sections

- Non-contact speed measurement at the turbine shaft and force sensor at the brake for measuring the torque

- Force sensor at the turbine inlet

- Speed, torque and pressure displayed on the switch cabinet of Characteristic Variables of Hydraulic Turbor Machines

- Water supply, flow rate measurement and data

- Processing software via Characteristic Variables of Hydraulic Turbornachines Unit

Technical Data:

- Turbine

- Output: approx. 350W at 1000min-1,150L/min,

- H=20m

- Max. speed: 1500min-1

- Pelton wheel

- 14 blades

- Medium diameter: 165mm

- Measuring ranges

- Torque: 0...9,81Nm

- Pressure : 0...4bar abs.

- Speed: 0...4000min-1

- Dimensions and Weight

- LxWxH: 580 x 485 x 476mm

- Weight: approx. 45kg

Enter Buying Requirement Details

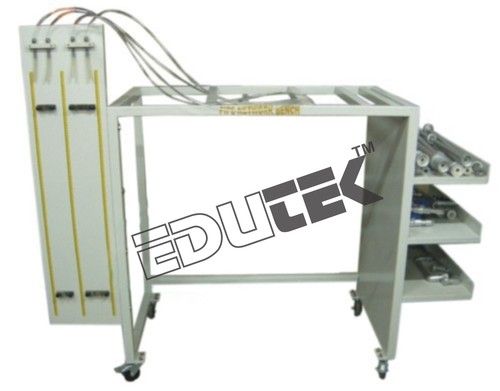

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |