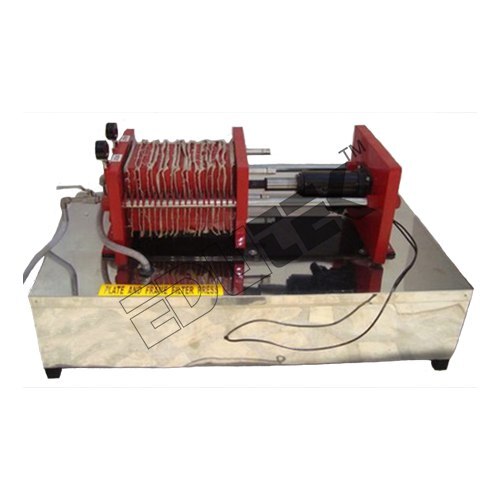

PLATE & FRAME FILTER PRESS APPARATUS

Product Details:

- Usage Mechanical Engineering Lab Equipment

- Application Mechanical Engineering Lab Equipment

- Product Type PLATE & FRAME FILTER PRESS APPARATUS

- Click to View more

PLATE & FRAME FILTER PRESS APPARATUS Price And Quantity

- 1 Piece

- 500 INR/Piece

PLATE & FRAME FILTER PRESS APPARATUS Product Specifications

- Mechanical Engineering Lab Equipment

- Mechanical Engineering Lab Equipment

- PLATE & FRAME FILTER PRESS APPARATUS

PLATE & FRAME FILTER PRESS APPARATUS Trade Information

- Cash on Delivery (COD) Cash Advance (CA) Cheque Telegraphic Transfer (T/T) Letter of Credit (L/C)

- Carton Box, Export Quality also Available

- Asia Middle East Africa

- All India

- ISO 9001, 14001, CE

Product Description

Specification:

PLATE & FRAME FILTER PRESS APPARATUS

Plate and frame filter presses areused in the beverage industry, for example, to clarify intermediate products.

A suspension of diatomite and water(recommended) is prepared in a stirred tank. The stirrer ensures that the solidremains suspended and does not settle. A pump delivers the suspension into theindividual separating chambers of the plate and frame filter press.

A separating chamber is formed by onefilter frame and two filter plates. The filter plates are grooved and coveredover with filter cloths. The filtrate passes through the filter cloth and flowsvia the grooves in the plates into a collecting pipe.

The filtrate exits the plate andframe filter press through the collecting pipe and is collected in the filtratetank. The solid material is separated off at the filter cloth, where it forms agrowing filter cake. As the filter cake becomes thicker, its flow resistancealso increases. When the separating chamber is full, or a maximum pressuredifference has been reached, the filtration process is ended.

The plates and frames of the plateand frame filter press are pulled apart. The filter cake can be removed. Forthe next filtration the plates and frames must be pushed back together. Aspindle is used to press them together.

The press forces ensure that thesuspension does not leak from the contact points between the plates and theframes, but is forced through the filter cloth.

The flow rate through the plate and frame filterpress is adjusted by a valve. The pressure occurring during filtration isindicated on a manometer. The filtrate tank is scaled. This means a stopwatchcan be used to measure the flow rate. An included opacimeter allows the solidconcentration of the filtrate to be determined. A drying chamber is recommendedfor evaluation of the experiments.

Product Description:

Power Source: Electric

Voltage: 240 V

Frequency: 50 Hz

Phase: Single Phase

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Mechanical Engineering Lab Equipment' category

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |