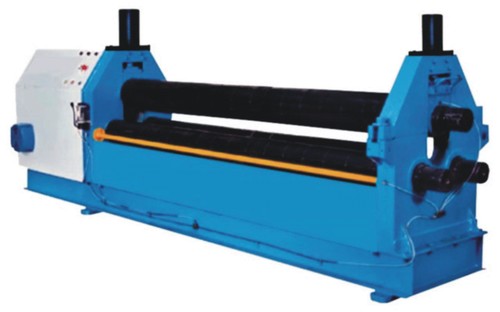

PLATE ROLLING MACHINE

Product Details:

X

Product Description

PLATE ROLLING MACHINE

Edutek Instrumentation are Manufacturer and Supplier Company in India,We are Exporter in India and other country 3 Roll assymmetrical mechanical Plate Bending M/c

Capacity: 4mm x 2500mm without pre-punching

- The machine adopts 3-roller asymmetrical structure with the upper roller as the main drive and the lower roller making vertical movement so as to clamp the plate materials tight. The machine drive comes from the engagement between the gear of the lower roller and the gear of the upper roller.

- The machine is the most precise 3-roll machine in its category. The RGS design reduces to a minimum the distance between the bending points guaranteeing higher bending accuracy.

- The Ultra wide roll support with lubrication circuit is mounted within linear slides to prevent wear and tear.

- The very high rotation power is a guarantee of the Machine superior rolling torque and speed, available without loss of energy as all three rolls are driven independently by Gear and gearboxes directly coupled to the rolls shafts.

- Max thickness of Steel Plate -10mm

- Max width of roll board -3200mm

- Yielding Limit of Sheet Metal -265Mpa

- Min rolling diameter of the Full Loading -500mm

- Top Roll Diameter -260mm

- Bottom Roll Diameter -160mm

- Distance between two down rolls -280mm

- Bending Speed 5.56 m/min

- Motor Power 11Kw

- Auxiliary Motor Power 7.5Kw

- Roll Housing Spherical roller bearings and bronze housings

- Bottom Roll Diameter 155 mm

- Working Speed 5 meter/min

- Bending rolls are made of alloy steel.

- The robust welded structure is made of UT tested IS: 2062 M.S. plates.

- The top roll adjustment is manual by screw jack.

- Main drive motor.

- Reverse / Forward roll drive with overload protection.

- Axletree: Double-row self-aligning bearing

- Programmable logic controller

- Automatic lubrication system which has block alarm

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Mechanical Engineering Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |