Pressure Distribution On A Cylinder

Product Details:

X

Product Description

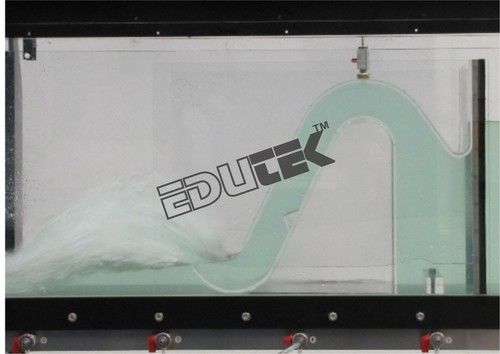

PRESSURE DISTRIBUTION ON A CYLINDER

The pressure distribution at bodies under incident flow, simple models such as semispherical shells, streamlined bodies or cylinders are used in fundamental experiments. Inciden flow of blunt models may lead to flow separation.

Used in conjunction with accessory makes it possible to record the pressure distribution around a cylinder under transverse incident flow. The cylinder is attached inside the intake pipe. The cylinder is fitted with a radial hole for pressure measurement and can be rotated around its axis. This means the pressure on the cylinder can be measured depending on the angle adjustment. The angl adjustment is detected electronically. The measured values are analysed using the software.

In addition, a total pressure sensor that can be moved transverse to the direction of flow makes it possible to record the velocity profile downstream of the cylinder and thus to measure the wake.

Part of a series that allows experiments on the principles of incompressible air flow. The software for data acquisition and visualisation makes the experiments especially clear and enables fast execution of experiments with reliable results.

The well-structured instructional material sets out the fundamentals and provides a stepby- step guide through the experiments.

- In conjunction with the Unit Air Flow Principles

- Measurement of the pressure distribution around a cylinder subject to transverse incident flow

- In conjunction with total pressure sensor

- Measurement of the total pressure in the wake of a cylinder

- Determine drag coefficient from the pressure distribution in the wake of a cylinder

- Demonstrate wake depression

Specification:

- Pressure distribution around a cylinder subject to transverse incident flow

- Accessory for the Unit Principles of Air Flow

- Cylinder with radial hole for pressure measurement

- Rotatable cylinder for pressure measurement at any angle adjustment

- Scale for angle adjustment

- Electronic detection of the angle

- In conjunction with total pressure sensor measurement of the total pressure in the wake of a cylinder

- Display and analysis of the measured values using the software in

- The Unit Principles of Air Flow

Technical Data:

- Cylinder

- Outer diameter: 25 mm

- Inner diameter: 21 mm

Dimensions and Weight:

- L x W x H: 290 X 90 X 50 m

- Weight: approx.4.5 kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |