Refrigeration Circuit With Variable Load

Product Details:

X

Product Description

REFRIGERATION CIRCUIT WITH VARIABLE LOAD

Refrigeration systems with two-stage compression are used for the generation of particularly low temperatures. At very low temperatures large pressure differences are required between the evaporator and condenser. In a compressor the volumetric efficiency drops significantly at high pressure ratios. Therefore, two compressors are connected in series, with each compressor only having a relatively low pressure ratio. This makes a more favourable dimensioning of the low pressure stage compressor possible. Due to the large specific volume it requires a larger capacity at lower drive power. In addition, intercooling between the low pressure compressor (LP) and the high pressure compressor (HP) reduces the outlet temperature of the HP compressor to harmless values and improves the efficiency of the compression.

The unit perform the following experiments and investigations:

Learning Objectives / Experiments

- Design and components of a refrigeration system

- Compressor

- Condenser

- Thermostatic expansion valve evaporator

- Pressure switch

- Representation of the thermodynamic cycle in the

- Log p-h diagram

- Determination of important characteristic variables

- Coefficient of performance

- Refrigeration capacity

- Compressor work

- Operating behaviour under load

Specification

- Investigation of a refrigeration circuit with water circuit as load

- Refrigeration circuit with compressor, condenser with fan, thermostatic expansion valve and coaxial coil heat exchanger as evaporator

- Water circuit with pump, tank with heater as cooling load at the evaporator

- Heater with controller to adjust the tank temperature

- Record of all relevant measured values and display directly at the location of measurement

- Software for data acquisition via USB under Windows Vista or Windows 7

- Refrigerant R134a, CFC-free

Technical Data

- Compressor

- Refrigeration capacity: approx. 380W at 5/40°C

- Evaporator

- Refrigerant volume: 0,4L

- Water volume: 0,8L

- Condenser

- Transfer area: approx. 1,25m²

- Fan power consumption: 4x 12W

- Pump

- Max. flow rate: 1,9m³/h

- Max. head: 1,4m

- Tank

- Volume: approx. 4,5L

- Heater: approx. 450W

Measuring ranges

- Pressure: 2x -1...15bar

- Compressor power: 1x 0...750W

- Temperature: 6x 0...100°C

- Flow rate (water): 1x 0,05...1,8L/min

Dimensions and Weight

- LxWxH: 1400x560x1800mm

- Weight: approx. 138kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

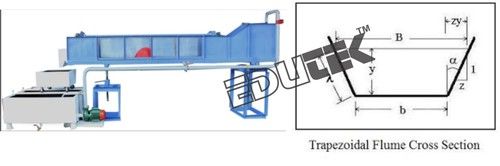

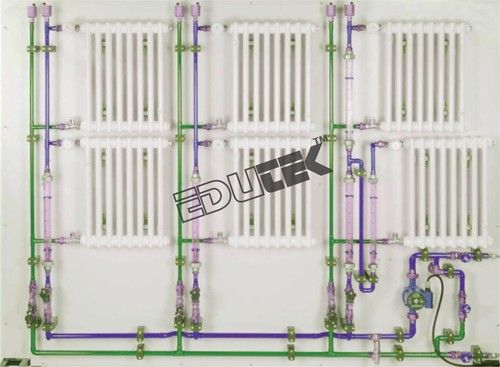

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |