Refrigeration System With Open Compressor

Product Details:

X

Product Description

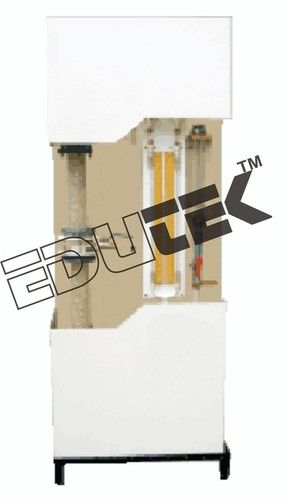

REFRIGERATION SYSTEM WITH OPEN COMPRESSOR

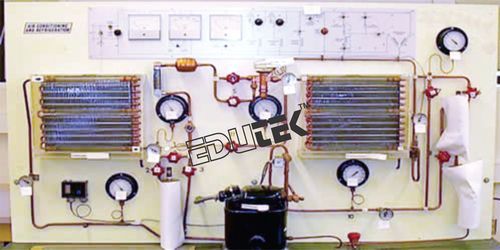

Basic experiments in the field of refrigeration. The trainer includes a closed refrigeration circuit with open compressor, a condenser with fan, a thermostatic expansion valve and an evaporator in a refrigeration chamber with transparent door. A fan in the refrigeration chamber ensures an even temperature distribution. A cooling load is simulated by an adjustable heater in the refrigeration chamber. The drive unit drives the compressor via a V-belt. The compressor speed is set at the . The circuit is equipped with a combined pressure switch for the delivery and intake side of the compressor.

All relevant measured values are recorded by sensors. Digital displays indicate the measured values. The simultaneous transmission of the measured values to a data recording software enables convenient analysis and the representation of the process in the log p-h diagram. The software also displays the important characteristics variables of the process, such as the refrigeration capacity and the coefficient of performance.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.The unit perform the following experiments and investigations:

Learning Objectives / Experiments

- fundamentals of refrigeration

- design and components of a refrigeration system

- open compressor with drive

- condenser

- evaporator

- thermostatic expansion valve

- pressure switch

- determination of important characteristic variables

- coefficient of performance

- compressor capacity

- refrigeration capacity

- compression ratio

- volumetric efficiency

- representation of the thermodynamic cycle in the

- log p-h diagram

- determination of the compressor efficiency

- effect of the compressor flow rate on the

- refrigeration circuit

Specification

- investigation of a refrigeration circuit with speed-controlled compressor

- refrigeration circuit with open compressor, condenser, thermostatic expansion valve and evaporator in refrigeration chamber

- cooling load in the refrigeration chamber adjustable via heater

- drive and speed adjustment of the open compressor via Universal Drive and Brake Unit

- condenser and evaporator with fan

- pressure switch to protect the compressor

- digital displays for pressure, temperature, flow rate, power and speed

- software for data acquisition via USB under Windows Vista or Windows 7

- refrigerant R134a, CFC-free

Technical Data

- Open compressor

- Refrigeration capacity: approx. 845W (at speed:

- 975min-1 and -10/40°C)

- Speed: 500...1000min-1

- Condenser with fan transfer area: 2,5m²

- Capacity: approx. 1935W at 25°C air temperature (ambient) / deltat=15°C

- Evaporator

- Transfer area: 3,62m²

- Capacity: 460W at 3°C air temperature (chamber) / deltat=13°C

- Heater power: 500W

Measuring ranges

- Temperature: 4x -5...105°C, 1x -50...250°C

- Pressure: 2x -1...15bar

- Speed: 1x 0...1000min-1

- Flow rate R134a: 1x 2...15g/s

- Power: 1x 0...500W

Dimensions and Weight

- LxWxH: 1470x800x1850mm

- Weight: approx. 185kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |