Replacement Of Refrigeration Components

Product Details:

X

Product Description

REPLACEMENT OF REFRIGERATION COMPONENTS

The replacement of a faulty compressor or other components of the refrigeration system are amongst the repeated activities of a mechatronics engineer for refrigeration. Allows for training in these processes. The consequences of incorrect procedures can be demonstrated. The components are integrated into an operational refrigeration system. This allows for the practical testing of the functionality of individual components after replacement. The following activities must be carried out e.g. after replacing a compressor:

- Refrigerant displacement (pump-down)

- Disconnection of the compressor at the service valves

- Disconnection of electrical connections

- Compressor replacement, correcting oil level, if necessary

- Reconnecting electrical connections

- Reconnecting the compressor with the service valves

- Evacuating the compressor and making the connection to the system

- Compressor test run, checking for leaks and replenish refrigerant, if necessary

- Checking the system pressures

Learning Objectives / Experiments

- Familiarisation with and carry out basic activities for the servicing of refrigeration systems

- Replacement of

- compressor

- pressure switch

- filter/drier

- solenoid valve

- expansion valve

- Refrigerant displacement (pump-down)

- Mechanical and electrical assembly and disassembly of components

- Replenish refrigerant and compressor oil

- Leak test

- Compressor test run

- Adjustment of expansion valve and pressure switch

Specification

- Trainer from the practical series for the training of mechatronics engineers for refrigeration

- Service exercises in refrigeration systems

- Complete refrigeration circuit with open compressor, air-cooled condenser, receiver and air cooling evaporator

- Replaceable components: compressor, filter/drier, pressure switch and solenoid valve

- Recommended accessories evacuation equipment and tool set [6] Overall arrangement on robust workbench

- Refrigerant R134a, CFC-free

Technical Data

- Open refrigerant compressor

- Drive power: 0,75kW

- Refrigeration capacity: 1245W at -5°C/36°C

- Maximum system pressure: 18bar

Pressure switch

- LP: -0.2...7bar

- HP: 10...32bar

Dimensions and Weight

- L x w x h: 1400x750x1650mm

- Weight: approx. 150kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

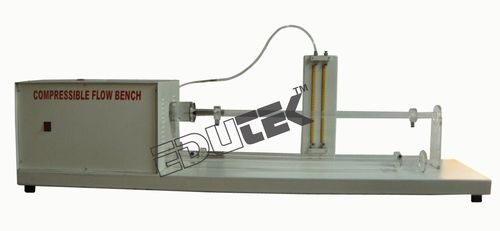

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |