ROD MILL APPARATUS

Price 500.0 INR/ Piece

ROD MILL APPARATUS Specification

- Application

- Mechanical Engineering Lab Equipment

- Product Type

- ROD MILL APPARATUS

- Usage

- Mechanical Engineering Lab Equipment

ROD MILL APPARATUS Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cheque, Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Packaging Details

- Carton Box, Export Quality also Available

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001, 14001, CE

About ROD MILL APPARATUS

Specification:

RODMILL APPARATUS

Rod Mills are horizontal rotating cylindrical steel chamber of half filled with steel rods of length slightly less than the length of chamber. The rods are of different diameter. The size reduction is accomplished by the impact of rods as they fall back after being lifted by the rotating chamber. Rod Mill is fitted on a sturdy MS frame.

Charging of rods and material is done by the means of opening provided in the chamber.

The chamber is turning about the horizontal axis through a reduction gearbox drive through a motor.

The stepped pulley arrangement is done for moving the Rod Mill at three different speeds.

A revolution counter is provided to find out the number of turns. Special arrangement is done to free the Rod Mill from reduction gearbox for charging and discharging the material.

Experimentation/learning objectives:

To determine the efficiency of a Rod Mill for grinding a material of known WI.

To study effect of RPM on the power consumption of a Rod Mill.

Utilities required:

Electric Supply: Single phase, 220 V AC, 50 Hz, 5-15 amp combined socket with earth connection. Earth voltage should be less than 5 volts.

Raw Material for Feed.

Sieve Shaker with set of sieves for analysis.

Floor area: 1.5m x 1.0m

Technical details:

Rod Mill : Material MS dia 275mm, Length 350mm. Thickness 4 mm(approx.) With rods of compatible size & quantity

Discharge Chute: Suitable size.

Drive: 1HP motor coupled to Reduction Gearbox & 3-step pulley.

Product receiver: Material Stainless Steel of suitable size.

Control Panel Comprises of:

RPM measurement: By proximity sensor with Digital indicator

Energy measurement: Electronic Energy meter.

MCB: For overload protection.

Standard make on/off switch, Mains Indicator etc.

The set-up is fitted with required guards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Engineering Lab Equipment Category

ELECTRICAL POWER ENGINEERING TRAINER

Price 400.0 INR / Unit

Minimum Order Quantity : 2 Units

Usage : ELECTRICAL

Accuracy : 100 %

Product Type : ELECTRICAL POWER ENGINEERING TRAINER

Display Type : DIGITAL

ENGINE PERFORMANCE TROUBLESHOOTING

Usage : Diagnostic and Training

Accuracy : High

Display Type : Analog and Digital

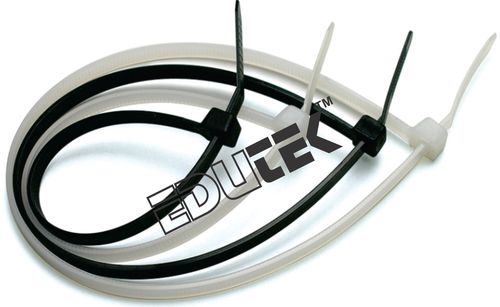

Cable Tie

Price 10.0 INR / Pack

Minimum Order Quantity : 1 Pack

Usage : Securing wires and cables

Accuracy : 100 %

Product Type : CABLE TIE

Display Type : NO DISPLAY

Zener .

Price 10.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Voltage regulation and stabilization

Accuracy : High

Send Inquiry

Send Inquiry