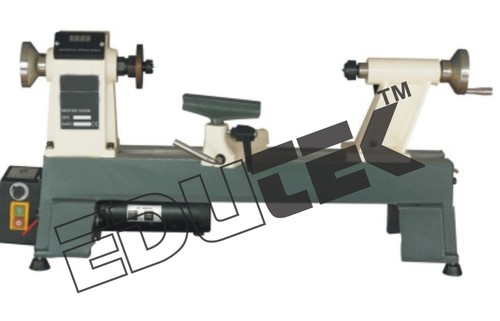

Woodworking Lathes Machine

Product Details:

- Feature Durable and efficient

- Core Components Motor Spindle Bed

- Capacity Customizable based on requirement

- Power Source Electric

- Model No WLM-3000

- Warranty 1 year

- Voltage 220V

- Click to View more

X

Woodworking Lathes Machine Product Specifications

- 1000x400x600 mm

- 1 year

- Woodworking lathe

- Analog

- 220V

- High precision

- 120 kg

- 50 Hz

- Variable speed operation

- Semi-automatic

- Ambient temperature

- Cast iron

- Durable and efficient

- Motor Spindle Bed

- Customizable based on requirement

- Electric

- WLM-3000

- Shaping and finishing wood

Product Description

WOODWORKING LATHES MACHINE

Use: Wood turning & copying with roughing and finishing

The machine using two cutting head (two knives) at the same time during the

turning cycle (one for cutting & one for finishing and each knife has scale of

the cutting depth.

- Max. distance between centers 1200mm

- Height of centers over bed 120mm

- Max. copying diameter 150 mm

- Max. diameter permitted by traveling steady 90 mm

- Connection for driving and tailstock centre CM 3

- Saddle feed speed 0 ·5 meter /min

- Saddle return speed 5 meter/min

- Spindle motor 2,9KW

- Variable Spindle speeds R.P.M. (900 - 1500 - 2200 3000)

The machine includes:

- Work- piece centering device that Permits the rapid centering of work-pieces.

- Tool support rest for occasional hand turning finishes.

FAQs of Woodworking Lathes Machine:

Q: What is the core component of the Woodworking Lathe Machine?

A: The core components of the Woodworking Lathe Machine include the Motor Spindle Bed.Q: What is the automation grade of the Woodworking Lathe Machine?

A: The automation grade of the Woodworking Lathe Machine is semi-automatic.Q: What type of display does the Woodworking Lathe Machine feature?

A: The Woodworking Lathe Machine features an analog display type.Q: What is the usage of the Woodworking Lathe Machine?

A: The Woodworking Lathe Machine is used for shaping and finishing wood.Q: What is the warranty period for the Woodworking Lathe Machine?

A: The Woodworking Lathe Machine comes with a 1-year warranty.Q: What is the power source requirement for the Woodworking Lathe Machine?

A: The Woodworking Lathe Machine operates on electric power source.Q: What materials are used in the construction of the Woodworking Lathe Machine?

A: The Woodworking Lathe Machine is constructed with cast iron materials.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

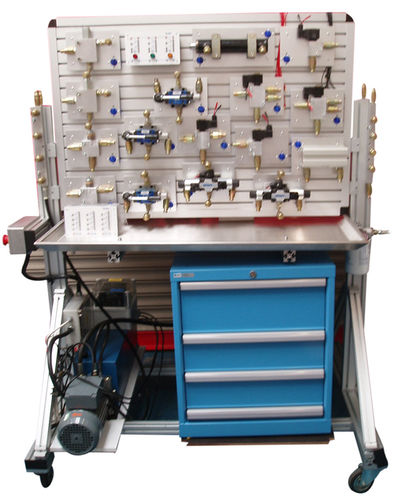

Other Products in 'Educational Trainer Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |