Computerized Pump And Hydraulic Turbine Study Unit

Product Details:

X

Product Description

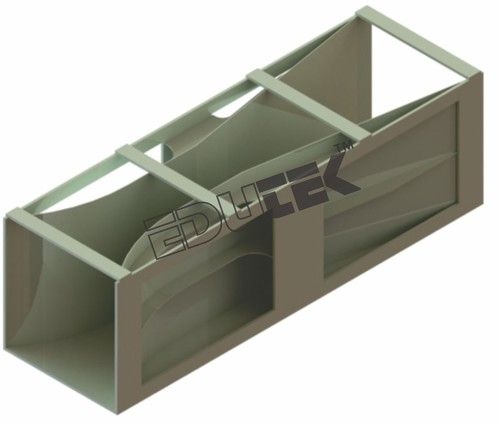

COMPUTERIZED PUMP AND HYDRAULIC TURBINE STUDY UNIT- The frame made of stainless steel AISI304, square section 30x30x2mmwith wheels dimensions: 1500x1000x1100h mm

- The feeding tank made of stainless steel AISI304, 25/10 thikness capacity 550 l

- The pump should have the following characteristics: centrifugal, axial suction power 4kW speed 2900rpm delivery

- 110÷315l/min head 57÷46m

- Manometer on the pump delivery the following characteristics:

- Measuring range 0÷6 bar case in AISI 304

- Wetted parts in AISI 316L nominal diameter 150 mm

- Precision class 1 equipped with potentiometer with 4-20mA output

- The flow transducer (pump delivery-turbines inlet) the following characteristics:

- Turbine type

- Measuring range 30÷350 l/min

- 2"G fittings

- 4-20mA output

- precision ±3%e.o.s.

- Made of PVC PN16 Dn50 have four separate branches: three to feed each turbine separately and a free discharge for the pump study have three ball valves made of PVC at the turbines inlet have a needle valve on the pump discharge

- Made of corrosion proof material rotor with 20 blades ago doble type nozzle adjustable deviation plate case made of transparent plexiglass

- The mini Francis turbine the following characteristics:

- Made of corrosion proof material 11 adjustable blades distibutor

- End cover made of transparent plexiglass

- The mini Kaplan turbine the following characteristics:

- Made of corrosion proof material 10 adjustable blades distibutor

- N°3 changeable rotors with four blades, each of them with a different blades angle end cover made of transparent plexiglass

- The turbines braking unit the following characteristics:

- D.c. permanent magnet servomotor rated current 5.4A rated voltage 48V

- Maximum power 210W at 3000rpm

- The speed sensor, connected to the braking unit, should have the following characteristics: inductive type transducer measuring range 0-15000rpm precision ±2%f.s.

- The connection between the braking unit and the turibne should be HELICAL type

- The monometer mounted at the turbines inlet should have the following characteristics: measuring range 0÷6 bar case made of stainless steel AISI 304 wetted parts made of stainless steel AISI 316L nominal diameter 150 mm precision class 1 equipped with a potentiometer with 4-20mA output

- The electric control board made of: Pump switch

- Amperometer with analogic output Voltmeter with analogic output

- Torque visualizer with analogic output. N°2 digital rpm meter with analogic output Flow visualizer with analogic output Resistive load

- Potentiometer for load regulation Potentiometer for pump speed regulation Electric feeding and signal conditioning unit, A/D board

- The acquisition and analysis software should: run in MS-Windows environment allow the automatic acquisition of the tranducers signals and the calculation of all the required parameter allow to visualize on the screen or print the acquired data versus time diagrams or the diagrams required for the exercises allow to save the acquired data and the calculated one in ASCII format making simulations typing the data

- The software run on a PC qwith the following minimum characteristics: Pentium con Hard Disk (> 10Gb) and CD drive

- Graphic card SVGA 800x600 Mouse RAM 32 MB min USB port

- Graphic printer MS-Windows ver. 95 or following

- Electric feeding: 220 V c.a. singlephase, 50/60 Hz

- Water feeding: to fill the feeding tank before use the unit

- Net weight: 450kg

- Dimensions: 1500x900x1500 h mm

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |