Flow Meter Trainer

Product Details:

X

Product Description

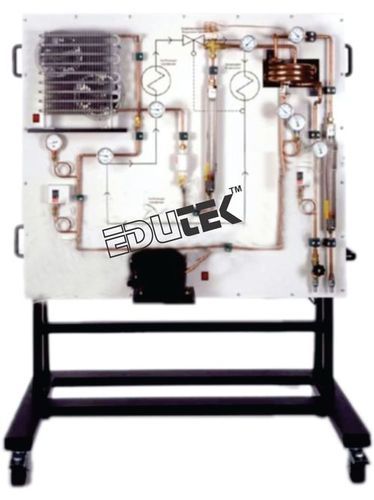

FLOW METER TRAINER

Flow measurement plays a key role in many process engineering systems. Different flow meters are used for this, depending on the medium and application. The trainer is used to examine different principles of operation of flow meters. The flow meters are available pressure loss curves and accuracies can be compared to determine which flow meter is suitable for which area of application.

One horizontally or vertically installed flow meter can be operated in a closed water circuit. The flow rate can be adjusted via a valve. A high-precision electromagnetic flow rate sensor is available as a reference for calibrating the flow meters. To be able to determine the pressure losses of the various flow meters, the trainer is equipped with two twin tube manometers and a differential pressure sensor. A DC voltage source ensures the power supply to the flow meters if required.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Learning Objectives / Experiments

- Together with different flow meters available as accessories

- Different flow meters and their principles of operation

- Calibration of different flow meters

- Position dependency of flow meters

- Plotting and comparison of pressure loss curves

Specification

- Comparison and calibration of different flow meters

- Water circuit with tank, pump and valve to adjust flow rate

- 2 measuring locations for vertical or horizontal installation of the flow meters under test

- Electromagnetic flow rate sensor for reference measurement

- 1 differential pressure sensor and twin tube manometers for measurement of pressure losses

- DC voltage source to supply the flow meters with auxiliary power

- Flow meters available as accessories

Technical Data

- Tank: approx. 55L

- Pump

- Max. flow rate: approx. 225L/min

- Max. head: approx. 11m

- DC voltage source

- Voltage: 24VDC

- Current: 2,0A

Accuracy of electromagnetic flow rate sensor

- 0.5% of final value

Measuring ranges

- Flow rate (reference): 0...4760L/h

- Differential pressure sensor: 0...2bar

- Twin tube manometers: 0...680mmWC

Dimensions and Weight

- L x W x H: 1820 x 690 x 1920mm

- Weight: approx. 116kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |