Hydraulic Circuit With Centrifugal Pump

Product Details:

X

Product Description

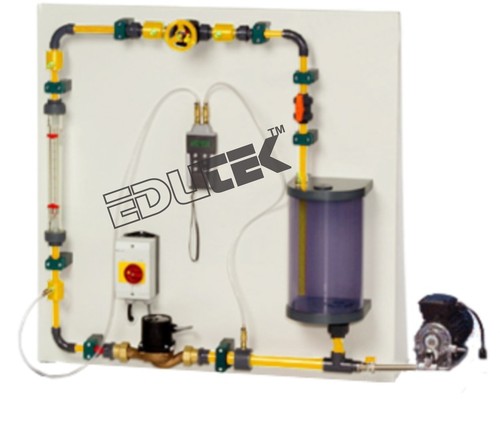

HYDRAULIC CIRCUIT WITH CENTRIFUGAL PUMP

Hydraulic circuits are designed according to their task and their area of application. Designing hydraulic circuits requires knowledge of flow behaviour and pressure losses in valves and fittings, as well as characteristics of the pump. A hydraulic circuit can be compared to an electrical circuit. This analogy can be made evident in the experimental unit.

The experimental unit includes a centrifugal pump, a rotameter, a diaphragm valve, a water tank and various other valves and fittings. After filling the system once the experimental unit can be operated independently from the water supply.

The flow is adjusted by valves and read off a rotameter. The pressure measuring points in the pipe system are designed as annular chambers. This creates a largely interference-free pressure measurement. Also supplied is an electronic pressure meter for differential pressure measurement. The pressure measurement points are connected in pairs to the pressure meter and the respective differential pressure read off the display.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Learning Objectives / Experiments

- Recording the pump characteristic

- Pressure losses at various valves and fittings depending on the flow

- Determination of the operating point in a hydrostatic circuit

Specification

- Pressure conditions at various measuring objects

- Measuring objects: pump, flow meter, diaphragm valve

- Centrifugal pump with 3 different speeds

- Closed water circuit

- Flow can be adjusted via valves

- Flow measurement using rotameter

- Annular chambers allow easy measurement of pressure

- Differential pressure measurement using electronic pressure meter

Technical Data

Tank

- Volume: 8,5L

Pump:

- Max. power consumption: 70W

- Max. flow rate: 5m³/h

- Max. head: 6m

- Three switching stages for speed selection

Measuring ranges

- Flow rate: 150...1600L/h

- Differential pressure: -350...350mbar

Dimensions and Weight

- LxWxH: 1320x610x1390mm

- Weight: approx. 98kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |