Impulse Turbine

Product Details:

X

Product Description

IMPULSE TURBINE

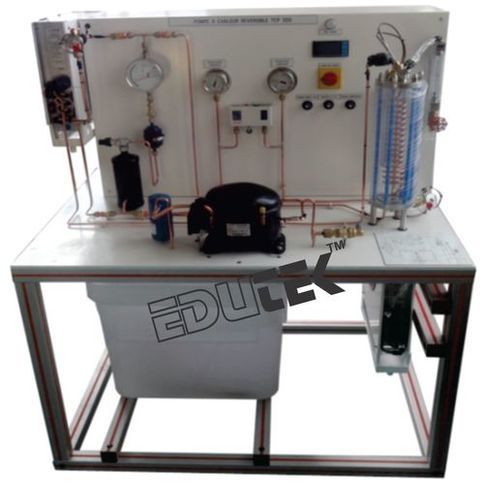

In impulse turbines, the working medium has the same static pressure in front of and behind the rotor. The conversion of pressure energy into kinetic energy takes place in the fixed nozzles of the distributor, not at the turbine rotor. This compressed-air driven experimental unit can be used to understand turbines powered by steam or water.

The is a single-stage, axial impulse turbine. The turbine consists of a rotor that is installed inside a transparent housing, a distributor with four nozzles and a band brake for applying a load to the turbine. The number of active nozzles can be adjusted by means of the valves. The compressed air velocity is increased in the nozzles. The air flow that hits the blades generates an impulse that causes the rotor to start moving.

The inlet and outlet pressure at the turbine are indicated on manometers. The turbine torque is determined by measuring the force on the band brake. The speed is measured with an optical speed sensor. Torque, speed and temperatures are digitally displayed. The air flow rate is measured with a rotameter and set by means of a valve.

The turbine is fitted with a solenoid valve as a safety device in case of overspeed. The brake drum on the turbine shaft is cooled by the compressed air.

The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Learning Objectives / Experiments

- Design and function of an impulse turbine

- Determination of torque, power and efficiency

- Graphical representation of characteristic curves for torque, power and efficiency

- Investigation of the effect of nozzle pressure and number of nozzles

Specification

- Investigation of a compressed air driven axial impulse turbine

- Transparent front panel for observing the operating area

- Distributor with 4 nozzles

- Selectable number of nozzles

- Applying a load to the turbine by using the band brake

- Setting the primary pressure with the pressure reducing valve

- Valve and flow meter for setting the flow rate

- Solenoid valve as a safety device to prevent overspeed

- Determination of the torque on the turbine shaft using a force sensor

- Measurement of the turbine speed with an optical speed sensor

- Manometer for displaying pressures on the inlet and outlet side

- Digital display of speed, torque and temperature

Technical Data

Axial impulse turbine

- Max. power: 50W at 15000min-1

Rotor

- Diameter: 55mm

- Number of blades: 28

Stator

- 4 nozzles, number can be selected

- Entry and exit angle: 20°

Measuring ranges

- Temperature: -20...1100°C

- Speed: 0...40000min-1

- Torque: 0...10Ncm

- Flow rate: 25...315L/min

- Inlet pressure: 0...2,5bar

- Outlet pressure: 0...0,1bar

- Primary pressure: 0...10bar

Dimensions and Weight

- LxWxH: 800 x 380 x 710mm

- weight: approx. 38kg

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |