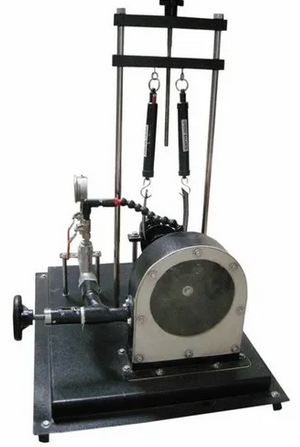

Operating Principle of Pelton Turbine

Product Details:

X

Product Description

Operating Principle of Pelton Turbine

- Water turbines are turbomachines utilising water power. The Pelton turbine is part of the free-jet turbines resp. impulse turbines which convert the pressure energy of water into kinetic energy entirely in the control device. During the conversion, the water jet is accelerated in a nozzle and directed onto the vanes of the Pelton wheel tangential. The water jet is redirected by approximately 180° in the vanes. The impulse of the water jet is transmitted to the Pelton wheel.

- The experimental unit consists of the Pelton wheel, a needle nozzle used as control device, a band brake for loading the turbine and a housing with a transparent front panel. The transparent cover enables you to observe the water flow, the wheel and the nozzle during operation. You can modify the nozzle cross-section and thus the flow rate by adjusting the nozzle needle.

- The structure easily installed in the basic hydraulic bench.

- The unit composed of a small size Pelton turbine.

- Be made of stainless steel.

- Transparent plexiglass cover for flow visualization.

- Develop a power of about 10W.

- A bourdon type manometer (range 0·2.5bar) measure the inlet pressure.

- A portable digital tachometer allow the speed measurement.

- Two dynamometers should allow the torque measurement and.

- Easy to functionality.

- Sturdy construction.

- Negligible maintenance.

The following characteristics:

- Spring type dynamometer.

- Range 0F·10N with 0.1N division.

- Pipe of 110mm dia with venturi meter.

- Pelton Wheel: 300 mm Diameter with 18 Buckets.

- Sump tank capacity: 200 liters High Grade Plastic.

- Flow rate measurement: Orifice meter with Burdon type pressure gauge.

- Pump : Monoblock type, 4 litre/sec, Head 20 mtrs; Motor 5 HP.

- Piping with necessary Valves and Fittings.

- Digital RPM Indicator.

- Detailed Technical Manual and On-site Training.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

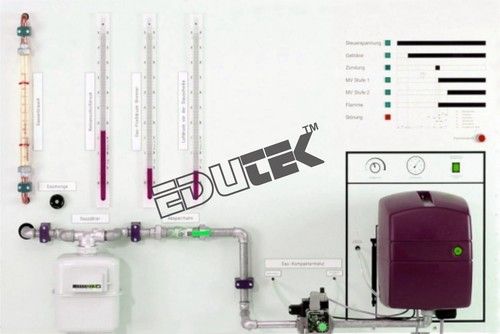

Other Products in 'Fluid Mechanics Lab Equipment' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |