Universal Process Control Trainer

Product Details:

- Temperature Range 0-100C

- Power Source Electric

- Model No UPC-123

- Automation Grade Semi-Automatic

- Core Components Sensors PLC Pneumatic components

- Accuracy High accuracy

- Frequency 50 Hz

- Click to View more

X

Universal Process Control Trainer Product Specifications

- High accuracy

- Suitable for process control training

- Variable capacity

- 50 Hz

- 1 year

- 220V

- Varied range for industrial processes

- 600x800x1200 mm

- Digital display

- Training equipment

- Sensors PLC Pneumatic components

- UPC-123

- Electric

- Semi-Automatic

- 0-100C

- 50 kg

- Stainless steel Aluminum

- Educational and industrial process training

Product Description

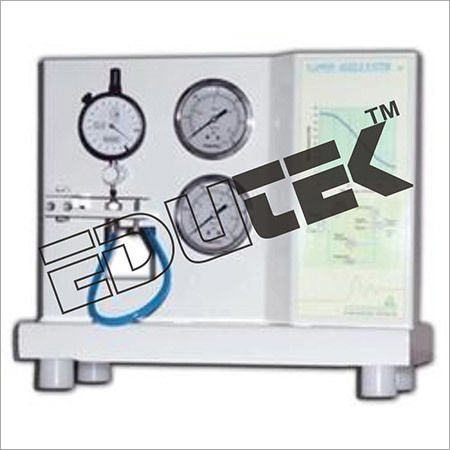

Universal Process Control Trainer

Objective

To demonstrate wide range of experiments, applications and advanced control techniques using industry standard instrumentation and controls.

Features

- DCS control.

- MOD BUS communication.

- SCADA software.

- Manual tuning and Auto tuning.

- Patchboard configurable experiments.

- Facility to introduce external controller.

- SS wetted parts.

- Inbuilt compressor and plunger pump with VFD.

- Study of I/P, DPT, control valve, valve positioner.

- Study of rota meter, orifice meter, venturi meter.

- Temperature, flow, level, pressure control.

- On-off, P, PI, PID control, PLC control.

- Open loop tuning by process reaction curve.

- Closed loop tuning by Zigler Nicholas method.

- Stability analysis by Bode plot.

- Cascade, Feed-forward and Ratio control.

- Three element control and interactive control.

FAQs of Universal Process Control Trainer:

Q: What is the frequency of the Universal Process Control Trainer?

A: The frequency of the Universal Process Control Trainer is 50 Hz.Q: What is the warranty period for the Universal Process Control Trainer?

A: The Universal Process Control Trainer comes with a warranty of 1 year.Q: What is the capacity of the Universal Process Control Trainer?

A: The Universal Process Control Trainer has a variable capacity.Q: What is the core component of the Universal Process Control Trainer?

A: The core components of the Universal Process Control Trainer include sensors, PLC, and pneumatic components.Q: What type of material is used in the construction of the Universal Process Control Trainer?

A: Stainless steel and aluminum are the materials used in the equipment of the Universal Process Control Trainer.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

+91

Email

Other Products in ' Process Control Equipments' category

"We deal all over World but our main domestic market is South India"

|

EDUTEK INSTRUMENTATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |